Product Features

- We utilize the Taiwan Delta temperature control module.

- Moreover, our machines offer customization options and feature auto cleaning, high precision, and high efficiency.

- Significantly, the aluminum alloy beam represents a relatively advanced approach, as its precision and straightness significantly outpace those of cast iron. Ultimately, stability and controllability stand as the most crucial factors for any machine joining a production line.

Details Images

Delta touch screen

Easily control and maintain the machine.Problems of the machine are visible in the panel.

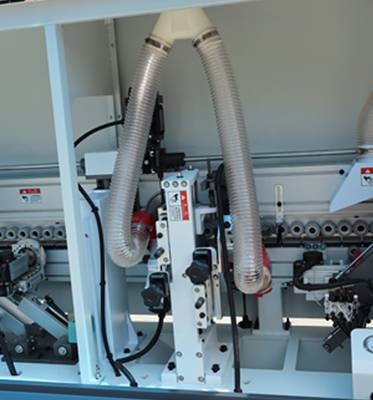

Pre milling

Solve defects such as burrs and slumps of the sheet to achieve better edge bangding effect.

Glue and press

The tape feeding device utilizes a knurled needle wheel structure, ensuring smoother tape feeding. Additionally, it features a digital hand wheel for the operator to adjust the pressing belt thickness.

End cutting

The end cutting mechanism employs precise guide rail movement and features an automatic tracking system with a high-frequency motor fast-cutting structure, thus ensuring a smooth cutting surface.

Fine trimming

The Fine Trimming knife actively removes excess edge banding from both the upper and lower sides of the board, thereby achieving a flat surface.

Corner rounding

The upper and lower four corners are processed into rounded corners, and the end surface of the board is smooth and beautiful.

Scrapping

It is used to eliminate the ripple marks produced in the trimming process and make the upper and lower parts of the sheet more smooth and tidy.

Buffing

Clean the board with a cotton buffing wheel to smoothen the edge-banding end.

OUR CERTIFICATES