Functional Description

Separation device – pre-milling – double glue pot – 6 -wheel scraper edge – end-cutting – rough trimming – fine trimming – four head corner rounding – double scraping edge – flexible flat scraping – double buffing – front and back cleaning –Baking lamp (crawler drive)

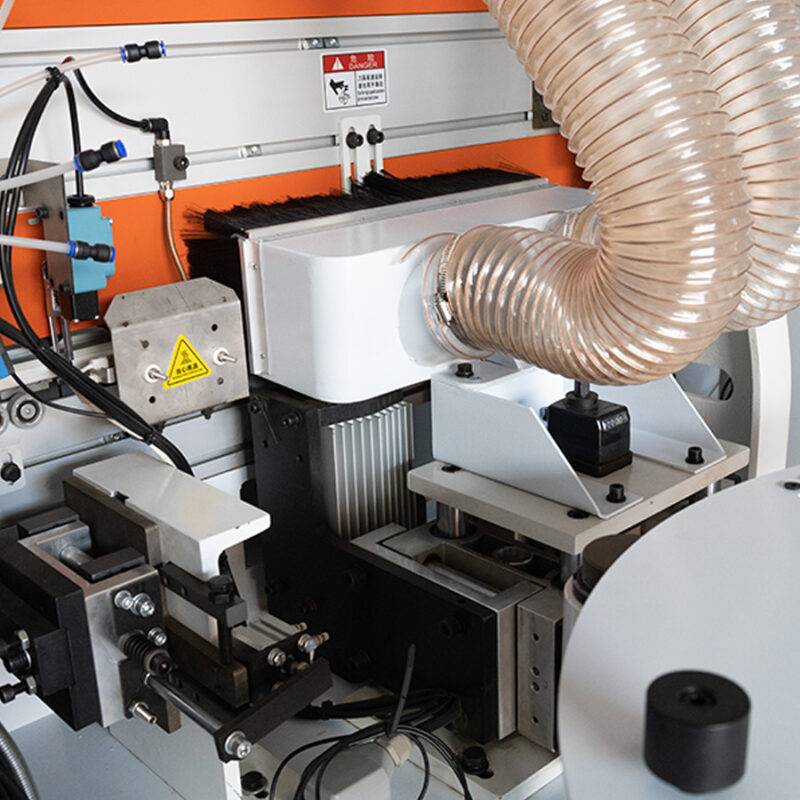

Pre-milling function:

◆ With built-in soot blowing device, milling one layer first to make the board smoother and the edge banding more close

Gluing device:

◆ The glue pot is more stable and glue is not easy to overflow.

◆The glue coating and tape feeding device adopts a knurled needle wheel structure, which makes the tape feeding smoother.

◆The distance between the guide plate and the glue coating device is controlled at about 0.1mm to ensure the quality of glue coating.

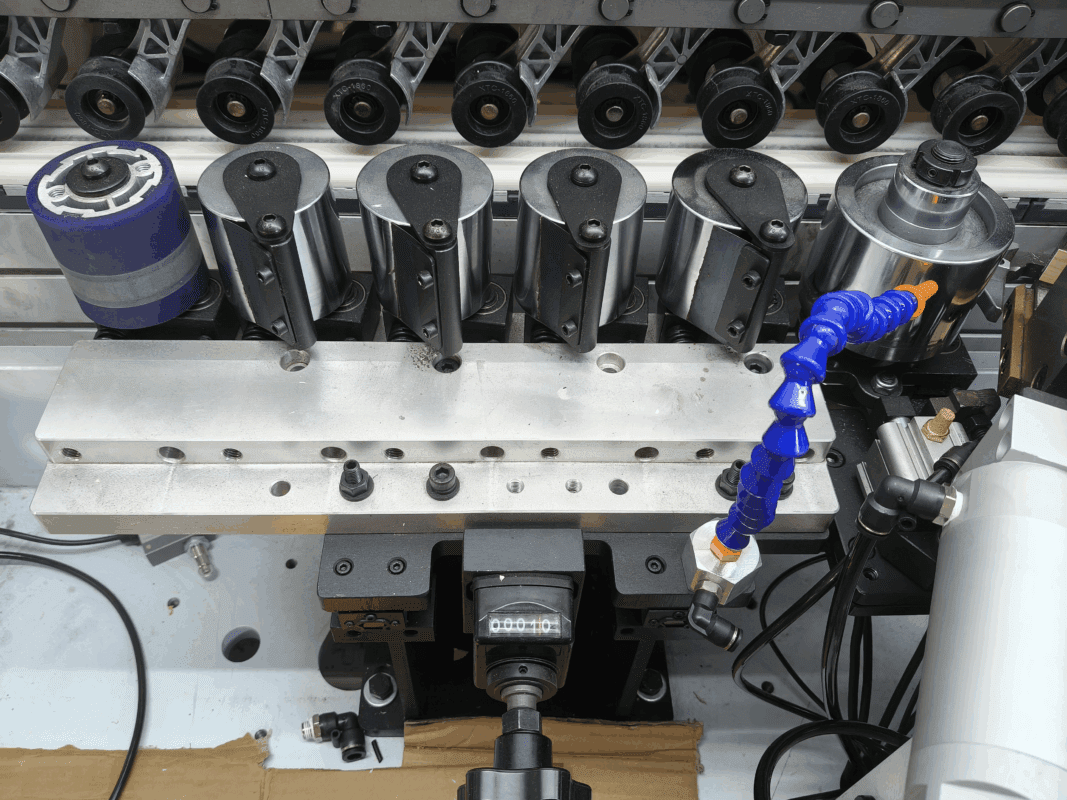

6-wheel scraper edge:

◆One active pressing wheel and five driven pressing wheels ensure a firm fit between the edge band and the panel.

◆Equipped with digital hand wheel to adjust the thickness of the pressing belt.

◆Each pressing wheel is equipped with a scraper to clean the residual glue on the pressing wheel simultaneously.

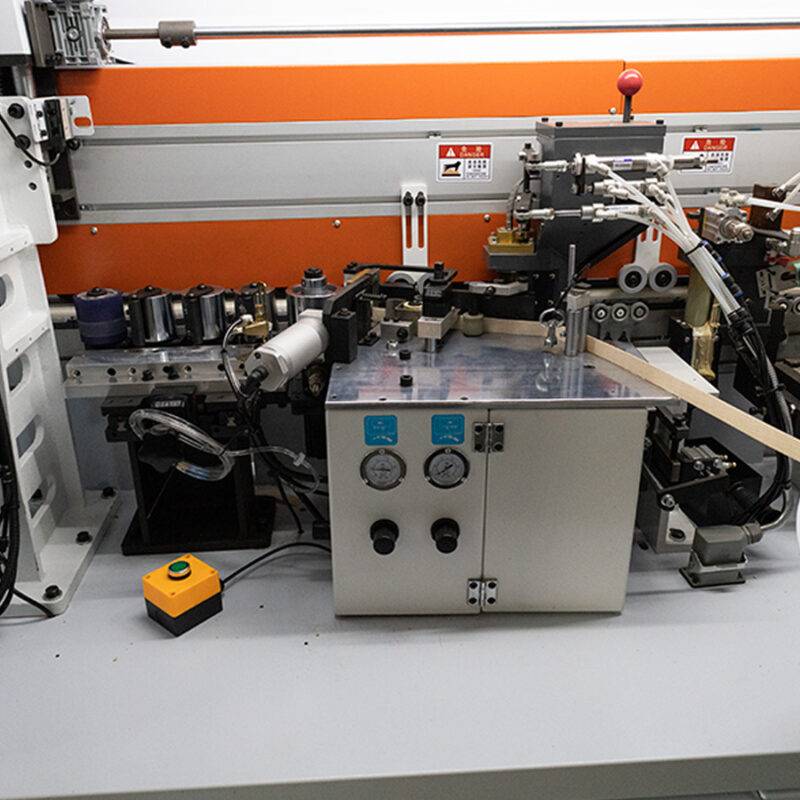

End-cutting device:

◆45 degree precision linear guide structure.

◆Two 0.37kw motors, speed: 12000rpm.

◆Adopt frequency converter control

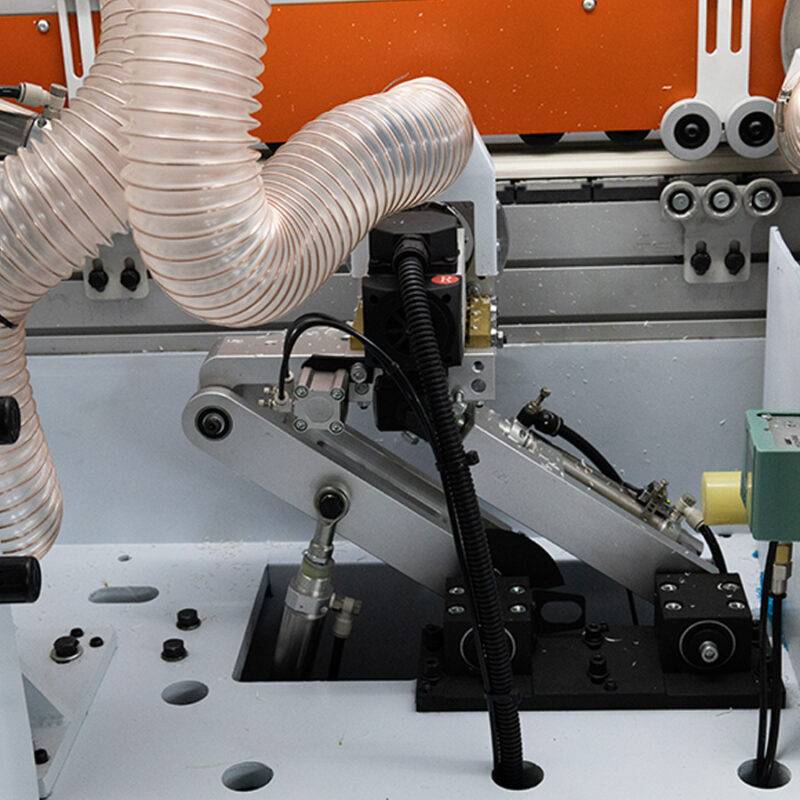

Rough trim device:

◆Two motors, each with a power of 0.75kw high-speed motor.

◆Two roughing milling cutters.

◆Equipped with independent dust cover

Fine trim device:

◆Two motors, each with a power of 0.75kw high-speed motor.

◆Two finishing milling cutters, specifications: (arc radius R1.5).

◆Equipped with digital hand wheel to adjust trimming thickness

◆Equipped with independent dust hood.

Four-head Corner rounding device:

◆4 motors, each high-speed motor with a power of 0.37KW.

◆4 tracking knives with 6 blades can achieve perfect contour tracking effect.

◆Equipped with digital hand wheel to adjust trimming thickness

◆Equipped with independent dust hood.

Scraping device:

◆Scraper blade radius R1.5.

◆Equipped with digital hand wheel to adjust scraping thickness.

◆Equipped with electronic pneumatic control blowing

Detergent device:

◆Spray cleaner before polishing to remove glue overflowing from the surface of the attached workpiece, reduce the problem of glue lines and plate stains, and improve the edge banding quality.

Electrical equipment:

◆Input voltage 3phase 380v, 50hz.

◆Independent inverter control with motor braking function.

◆Phase sequence protection device.

◆All equipment and electrical appliances comply with relevant national standards.

Controls system:

◆Adopt 15-inch brand touch screen.

◆Adopt Taiwan Delta temperature control module