CNC sponge cutting machine: an efficient and accurate sponge forming tool,

CNC sponge cutting machine is an automated equipment,that uses computer numerical control technology,and is specially used for high-precision,high-efficiency cutting of sponge materials of various densities.has become an indispensable,core equipment for modern sponge product production (such as furniture, mattresses, packaging linings, automotive interiors, sporting goods, etc.).

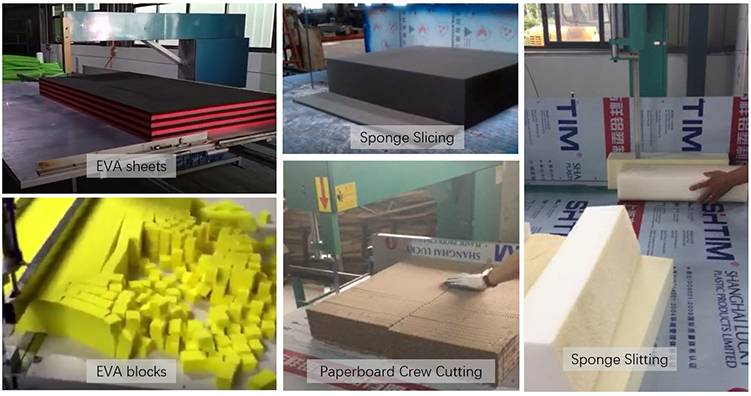

Samples Cut By CNC Sponge Cutting Machine

Its core working principle is to pre-program the cutting path and parameters through the computer (CAD/CAM software completes the design), and accurately control the cutting head to perform high-speed and complex movements on the X, Y, and Z axes or even multiple axes. The incision is smooth and free of debris; the vibration knife adopts high-frequency micro-vibration cutting, which is suitable for cutting harder or composite materials.

The core advantages are significant:

1. Excellent efficiency: Automated continuous cutting, fast speed, greatly improves production efficiency and shortens delivery cycle.

2. High material utilization: Intelligent nesting software optimizes the cutting path, minimizes corner waste, and significantly reduces raw material costs.

3. Good incision quality: The hot wire cutting edge is smooth and dust-free; the vibration knife cutting edge is neat.

4. High degree of flexibility: Changing products only requires changing the program, without making expensive molds, which is particularly suitable for small batch and multi-variety production.

Mechanical manufacturing is the cornerstone of the country’s industry. With more than ten years of experience in manufacturing machinery, we focus on the design of precision parts and equipment. If you have any questions or suggestions, please leave us a message below. Thank you for your browsing~