Precision Engineering for Enhanced Security

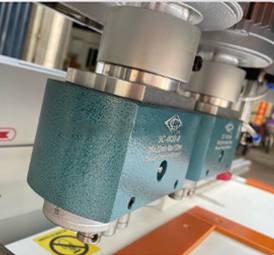

CNC Door Lock Machine machines utilize CNC (Computer Numerical Control) technology to drill, mill, and shape lock holes and grooves with micron-level accuracy. Whether working with wood, metal, or composite materials, they ensure that every cut meets strict industry standards. This precision is critical—misaligned holes or uneven grooves can compromise a lock’s durability and security, making these machines indispensable for manufacturers and locksmiths.

Key Features and Advantages

-

Automated Efficiency: Modern machines reduce human error and speed up production, making them ideal for large-scale manufacturing.

-

Versatility: They can process various lock types, from traditional mortise locks to advanced electronic systems.

-

Enhanced Security: Precise grooves and holes prevent forced entry and ensure smooth key operation.

The Future of Lock Processing

As smart locks and IoT-based security systems gain traction, these machines are evolving to support laser cutting and 3D milling for even greater precision. Innovations like AI-assisted alignment are also emerging, further enhancing efficiency and reliability.

From residential doors to high-security vaults, Door Lock Hole and Groove Processing Machines are the backbone of secure, long-lasting locking systems. Their continued advancement ensures that security technology keeps pace with modern demands