The Multi-Spindle Hinge Drill: Unlocking Precision and Efficiency in Woodworking

Cabinet makers and woodworkers know the challenge of drilling hinge cup holes all too well. This repetitive process determines how well each door aligns, swings, and looks. While a standard drill press or handheld drill can handle the task, it becomes slow and tedious with multiple doors. The Multi-Spindle Hinge Drill solves this problem—a specialized tool that transforms this essential step.

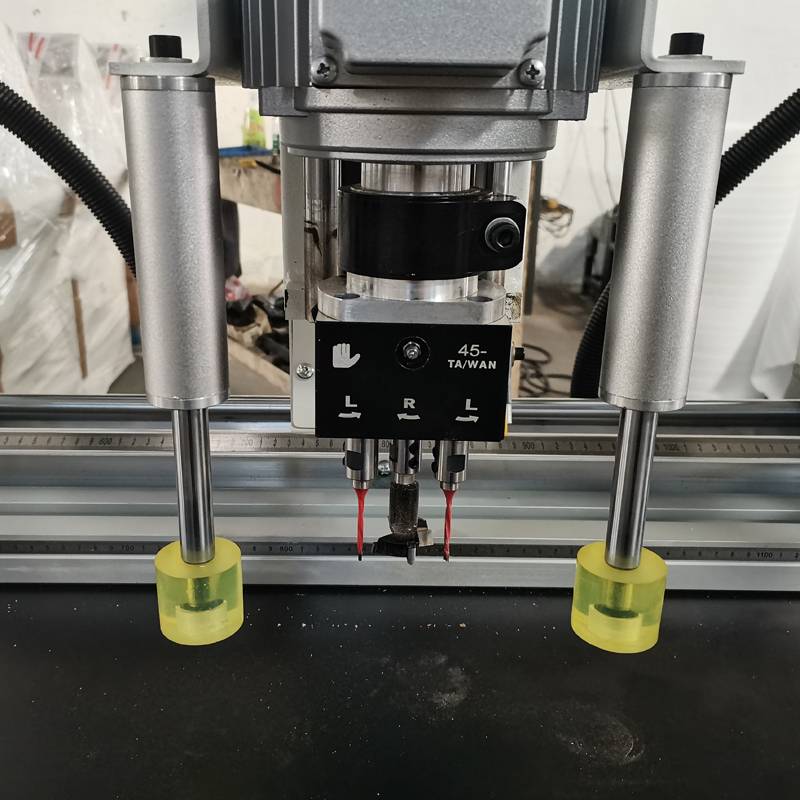

A multi spindle hinge drill, also known as a multiple boring machine, is a power tool featuring several drill bits mounted on a single head. Its spindles maintain precise spacing to match standard hinge patterns, like the popular 32mm system used in European-style cabinets. With one motion, the operator can drill all holes for a set of hinges at the same time.

Multi spindle hinge drill this machine performs one key function exceptionally well: it bores multiple perfectly aligned hinge cup holes in one swift operation.

1. Simultaneous Drilling: The tool drives several drill bits at once. Common models include 2, 3, or 5 spindles, allowing users to drill all holes across a door stile in a single pass.

2. Precision Alignment: A rigid jig or plate keeps the spindles fixed at exact intervals. This design guarantees consistent spacing and eliminates measurement errors.

3. Adjustable Depth Stop: Users can pre-set the drilling depth to ensure each hole fits the hinge cup flush with the surface.

4. Template Compatibility: Most models work with a fence or template. This setup positions the workpiece accurately for consistent edge distancing.

1. Saves Time: drastically reduces drilling time. Instead of taking hours, the work finishes in minutes.

2. Ensures Consistency: Removes human error. Every hole is perfectly spaced, making doors hang uniformly.

3. Increases Productivity: Cuts labor time per unit, allowing shops to take on more projects.

4. Reduces Fatigue: Minimizes the mental and physical strain of repetitive tasks.

5. Delivers Professional Quality: Helps achieve a factory-grade finish that manual methods struggle to match.