With the continuous development of technology, the woodworking industry has also ushered in a wave of intelligentization. As a leader in this field, CNC mortising machines, with their high efficiency, precision, and flexibility, have become a key piece of equipment in modern woodworking production lines. This article will provide a detailed introduction to the structure, operating principle, application areas, and future development trends of CNC mortising machines.

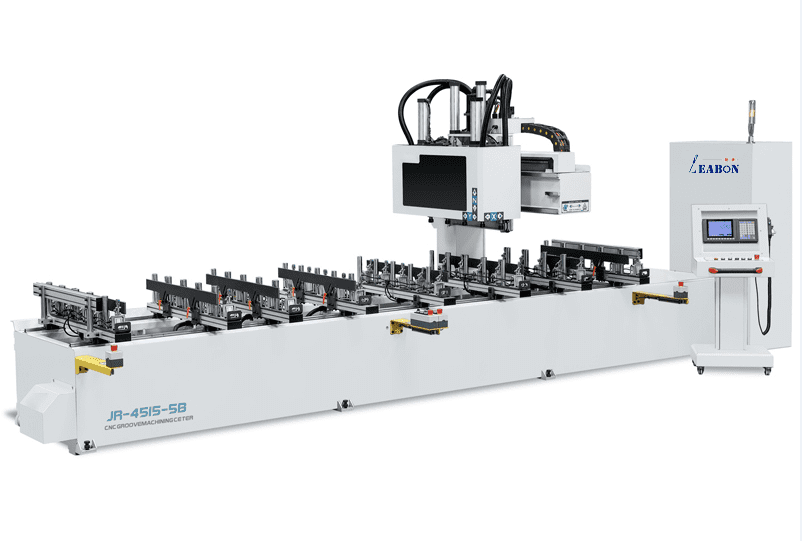

1. Structure and Features of a CNC Mortising Machine

(1) The use of CNC technology can achieve automated and continuous production, greatly improving production efficiency.

(2) Through high-precision control systems and servo motor drives, processing accuracy and stability are guaranteed.

(3) Tools and fixtures can be quickly replaced according to the processing requirements of different workpieces, achieving multiple uses of one machine.

(4) Multiple safety protection measures are adopted to ensure the safety of operators.

2. Working Principle of a CNC Mortising Machine

3. Applications of CNC Mortising Machines

In short, CNC mortising machines have demonstrated significant advantages and value in the field of woodworking manufacturing. As an efficient equipment integrated with a computer numerical control system, it realizes automated, high-precision groove processing, greatly improving production efficiency. Whether it is a rectangular, circular or other complex-shaped groove, the CNC mortising machine can easily cope with it and meet diverse production needs. It is easy to operate and easy to use, and even ordinary workers can master its operating skills in a short time. In addition, the application of five-axis CNC technology further improves the flexibility and accuracy of processing, reduces manual intervention, and ensures the stability of product quality. In short, the CNC mortising machine has become a powerful assistant to the woodworking manufacturing industry with its high efficiency, precision and convenience, and has promoted the rapid development of the industry.