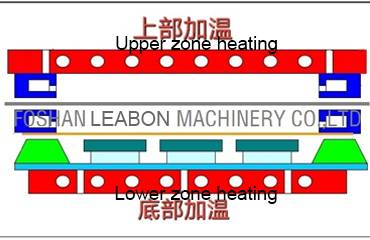

The core principle behind this technology is atmospheric pressure. The machine consists of a flexible membrane that creates an airtight chamber. The object to be laminated, along with the adhesive-coated laminate film, is placed inside. Once the air is pumped out, atmospheric pressure presses the membrane uniformly onto the object’s surface with immense force, conforming the laminate perfectly to every curve and detail.

This process offers unparalleled advantages. It eliminates bubbles and wrinkles that are common pitfalls in manual application. It ensures a consistent, high-quality finish on intricate profiles that would be impossible to cover using roller-based machines. Additionally, it is highly efficient, capable of processing multiple pieces in a single cycle.

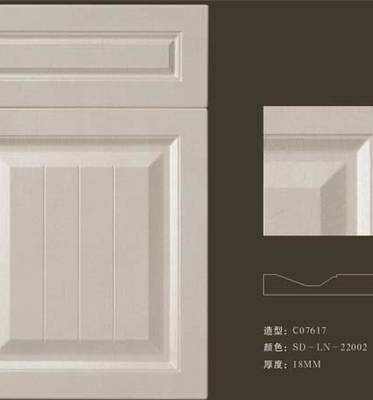

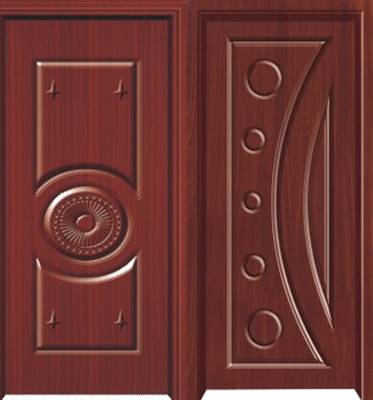

Vacuum laminators are essential for producing modern furniture with raised-panel doors, ornate details, and seamless wrapped edges. They are the key to achieving the flawless, durable surfaces required in high-end cabinetry and architectural millwork.

In summary, the vacuum laminator is a vital tool for advanced woodworking. It unlocks design possibilities for complex shapes, ensuring a perfect, durable finish that meets the highest standards of quality and aesthetics.