The wood industry begins by cross-cutting logs.

Yet, manual methods are labor-intensive and inefficient.

Moreover, they struggle to guarantee consistent accuracy.

Therefore, a Log Saw Machine is key to boosting productivity.

This article explores its definition and core benefits.

Additionally, it provides crucial tips for choosing the right one.

What is a Log Saw Machine?

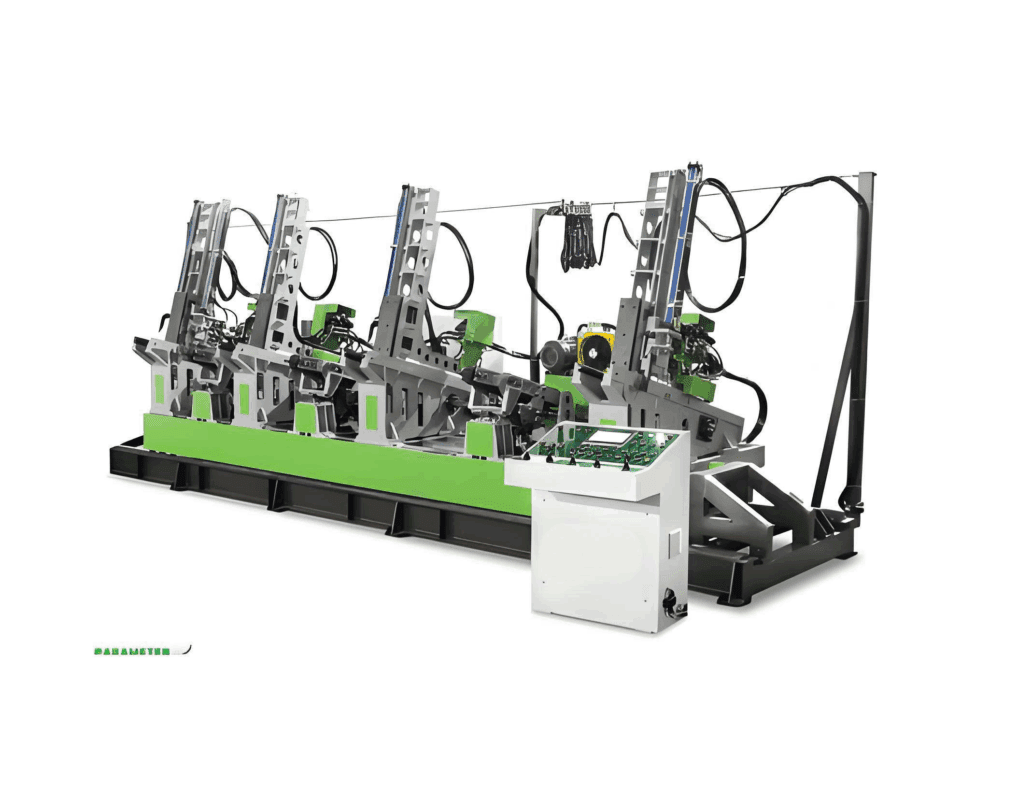

A Log Saw Machine, or log cutter, primarily cross-cuts whole logs into set lengths.

It then uses a powerful motor to drive a large circular or bandsaw blade.

Consequently, the machine makes fast and clean cuts through various wood types.

Furthermore, modern versions often incorporate hydraulic or servo systems.

As a result, they automate feeding and positioning for high-efficiency operation.

Key Advantages of Using a Log Saw Machine

Investing in a professional Log Saw Machine offers significant advantages over traditional methods:

Exceptional Production Efficiency:

1.Automated Operation: Features like automatic feeding, measuring, and cutting allow for continuous operation. A single operator can often manage multiple machines, increasing output exponentially compared to manual labor.

2.Continuous Duty Capability: Built with robust power systems and stable structures, these machines are engineered for long-term, high-intensity production cycles.

Superior Cutting Precision

1.Consistent Dimensions: Precision positioning systems and CNC controls ensure every piece of wood is cut to the exact same length with minimal tolerance, providing an excellent foundation for subsequent processing stages.

2.Clean, Smooth Cuts: Sharp blades and stable feed rates result in smooth, splinter-free end cuts, reducing material waste and the need for additional finishing.