For centuries, skilled hands and traditional tools defined furniture making. Human craftsmanship inevitably introduced minor imperfections. Then a technological revolution quietly reshaped the workshop. It introduced unprecedented accuracy and productivity. The furniture CNC router powers this transformation. It is redefining the very possibilities of woodworking.

1. Modern furniture CNC router completely win the quest for flawless precision.

2. Unlike manual cutting, it relies on a computer’s control.

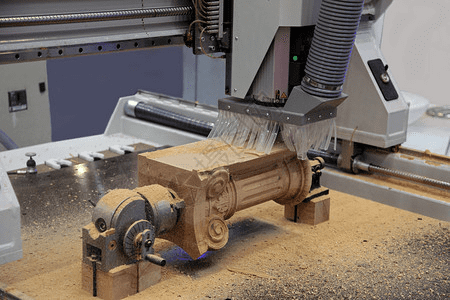

3. The machine follows digital designs with microscopic accuracy.

4. It executes every cut, carve, and joint with perfect repeatability.

5. You can produce a single intricate headboard.

6. You can also make a batch of fifty identical cabinet doors.

7. The CNC router guarantees each piece matches the digital blueprint.

8. This process eliminates human error.

9. It ensures a flawless fit every time.

Furthermore, the efficiency gains brought by a furniture CNC router are transformative for any business. Traditionally, complex projects required multiple setups, tool changes, and meticulous measurements, all consuming valuable time. In contrast, a furniture CNC router automates the entire machining process. Once the design file is loaded, the machine executes the program tirelessly, often performing the work of several artisans in a fraction of the time. This automation allows workshops to accelerate,their production cycles dramatically and take on more complex projects with confidence.

In conclusion, the integration of a furniture CNC router is no longer a luxury,for niche manufacturers; it is a powerful strategic investment for any forward-thinking furniture workshop. By mastering the blend of digital design and automated machining, this technology unlocks a new era of quality, speed, and creativity. Ultimately, embracing the power of the furniture CNC router is the key to building a more precise, efficient, and competitive future in the world of furniture making.