In the furniture manufacturing industry, applying veneer to curved furniture and special-shaped components has always been a daunting challenge. Due to the complexity of these curved surfaces, traditional manual veneer veneering often results in issues such as bubbles, warping, and wrinkles. These issues not only affect the aesthetics of the product but can also reduce its durability and lifespan. To address these challenges, curved surface positive and negative pressure presses have emerged as a proven process solution. Today, we’ll explore how curved surface presses improve yield rates from a technical perspective.

01How Does The Curved Surface Positive And Negative Pressure Press Work?

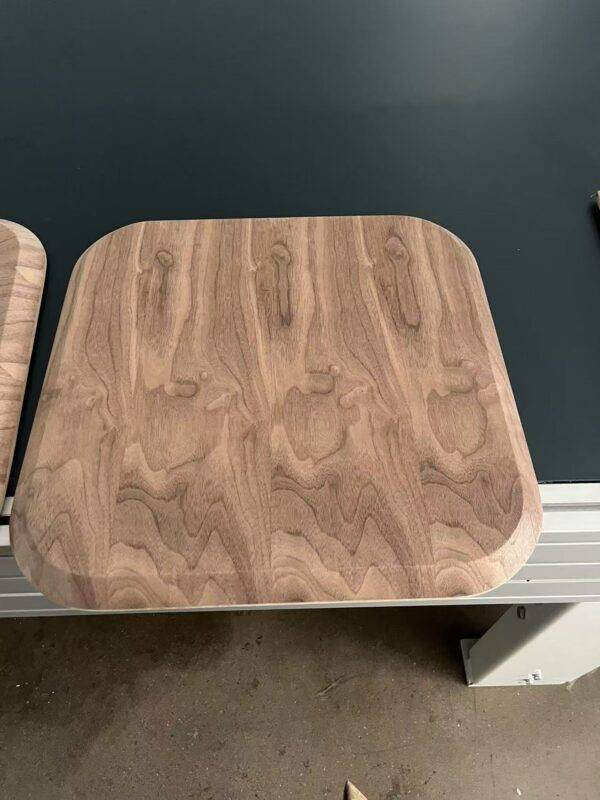

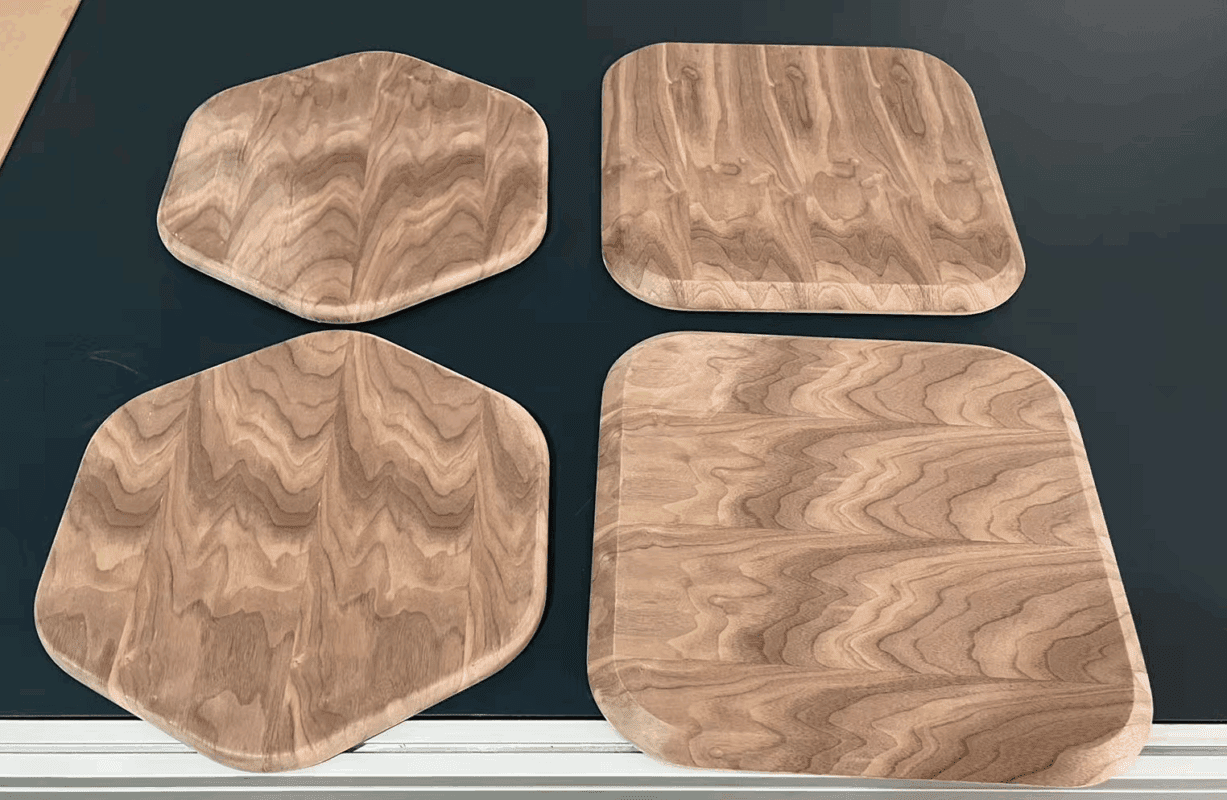

The curved positive and negative pressure press is a mechanical device specifically designed for laminating veneer to curved furniture and decorative surfaces. Its core function is to achieve a tight, bubble-free bond between the veneer and the curved substrate through controlled pressure, temperature, and time. This device utilizes positive and negative pressure technology, combined with an intelligent control system, to ensure uniform force distribution during the lamination process, thereby preventing bubbles and warping.

Core Features >>

1. The press can precisely control the applied pressure based on the curved surface shape and veneer material, ensuring a tight bond between the veneer and substrate.

2. By electrically heating the thermal oil, the press can quickly heat up and maintain a uniform temperature, ensuring the veneer and substrate are bonded at the optimal temperature.

3. The operator can set the bonding time via the PLC human-machine interface, ensuring precise control of the bonding process.

Technical Advantages >>

1. Utilizing a PLC human-machine interface, the operator can set and display parameters such as pressure, temperature, and time, achieving precise control. This intelligent control system not only improves operational convenience but also reduces human error.

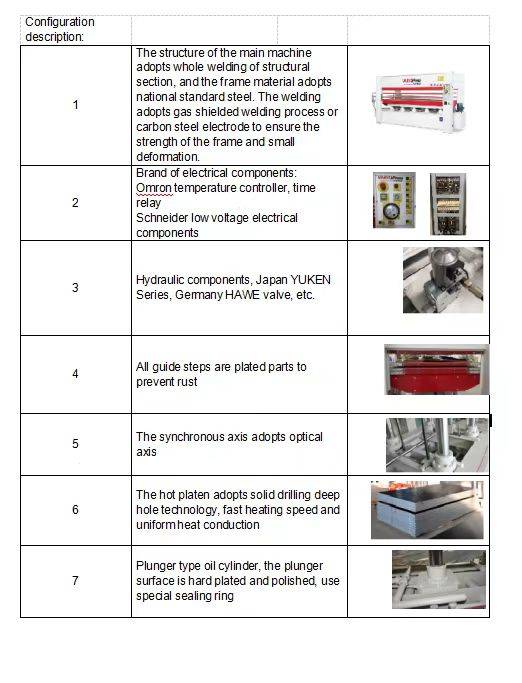

2. Major electrical components are from renowned brands such as Siemens, Inovance, Omron, and Schneider. The hydraulic valves are oil-based, and the cylinders are plunger-type. Heat-treated, ground, and hard-chrome-plated, these components ensure stable performance. The use of these high-quality components significantly enhances the reliability and service life of the equipment.

3. The electric heating heat transfer oil method is adopted, and the hot pressing plate adopts the solid steel plate deep hole drilling process, which has a fast heating speed, uniform heat conduction and low heat energy consumption. This heating method not only improves the bonding efficiency, but also reduces energy consumption

02 Manual Lamination VS. Automation

Operational Consistency >>

Manual lamination relies on the worker’s experience and proficiency, making it difficult for novices to master the process and resulting in poor consistency. Variations between workers can lead to inconsistent product quality. Automation, on the other hand, offers PLC touchscreen control, simple operation, and parameterized settings, ensuring high lamination accuracy and stability. The equipment precisely follows pre-set parameters, ensuring consistent lamination every time.

Quality Stability >>

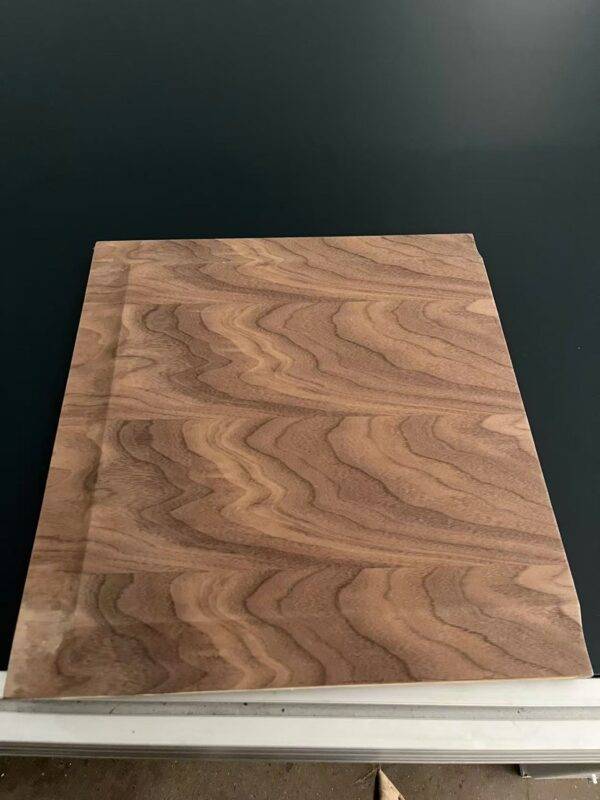

Manual lamination can lead to uneven pressure and speed, which can easily cause bubbles, wrinkles, and warping, affecting both aesthetics and durability. These issues not only increase rework rates but also reduce overall product quality. Automation, on the other hand, precisely controls parameters such as pressure, temperature, and time, eliminating the bubbles, wrinkles, and delamination that can occur with manual lamination. The resulting yield rate for finished products is significantly higher than with manual lamination.

Production Efficiency and Cost >>

Hand veneer lamination is slow, unable to meet the demands of large-scale production, and has high labor costs. The low efficiency of manual veneer lamination results in long production cycles, making it unable to meet the efficiency requirements of modern furniture production. However, automated production can be continuous and automated, far exceeding manual labor speeds. This significantly reduces labor costs per unit, making it suitable for large-scale mass production.

Material Adaptability and Waste >>

Manual veneer lamination carries a high risk of material waste. A single error can ruin both the veneer and the base material, significantly increasing material costs, especially for precious veneers. However, automated production offers significant efficiency, high lamination precision, and minimal material waste, resulting in significant cost advantages.

03 Application of Curved Surface Presses in Furniture Production

Curved surface presses with positive and negative pressure are suitable for applying curved veneer to components such as door core panels, kitchen cabinet panels, door moldings, wall panels, office desks, and hotel furniture. They are widely used by furniture manufacturers and interior decoration companies, including wooden door and cabinet factories. By introducing curved surface presses, these companies have not only improved production efficiency but also significantly enhanced product quality and reduced production costs.

04 Conclusion

From a technical perspective, curved surface positive and negative pressure presses can effectively resolve issues such as bubbles, warping, and wrinkles in the lamination of curved veneers, significantly improving product yield. For furniture manufacturers, curved surface presses not only improve production efficiency but also reduce production costs, enhancing product competitiveness. In today’s pursuit of efficient and high-quality production, curved surface presses are undoubtedly the ideal choice for furniture manufacturers seeking technological upgrades.