In the field of custom solid wood furniture, the demand for custom-made solid wood furniture is showing a continuous upward trend. However, traditional production models face many thorny challenges, which not only restrict production efficiency but also affect the market competitiveness of enterprises. This article will explore how advanced equipment and technology can help solid wood furniture manufacturers break through efficiency bottlenecks and achieve efficient and rapid delivery.

01 Common Challenges Faced by Solid Wood Furniture Factories

02 Precise Material Cutting: Improving Efficiency and Reducing Costs from the Source

In the production process of custom solid wood furniture, precise material cutting is a crucial step to ensure the smooth progress of subsequent processes. Shikainu’s precision cutting saw provides strong support for this step with its superior performance. This equipment integrates intelligent material selection, precise length cutting, and material calculation, combining multiple functions into one device. It can quickly and accurately cut materials according to different production needs, greatly improving the efficiency and precision of material cutting. Precise material cutting not only reduces material waste and lowers production costs, but also lays a solid foundation for subsequent mortise and tenon processing, ensuring the smooth operation of the entire production process.

03 Modular and Automated Processing of Mortise and Tenon Joints

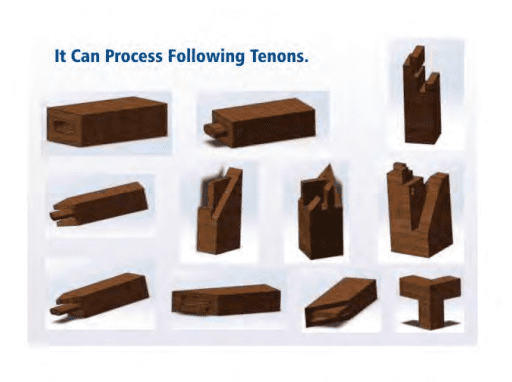

The mortise and tenon structure is the soul of solid wood furniture; its processing precision and efficiency directly affect product quality and delivery speed. Mortise and tenon machining centers, with their high-speed processing capabilities and diversified production features, have revolutionized mortise and tenon processing. They can quickly complete various types of mortise and tenon processing tasks, covering 95% of the conventional mortise and tenon structures on the market. The modular production method eliminates the need for users to calculate complex processing data; they only need to input basic information such as material specifications, and the equipment can automatically complete the processing, greatly reducing operational difficulty and error rates. Whether it’s a 90° or 45° mortise and tenon structure, this equipment can handle it with ease.

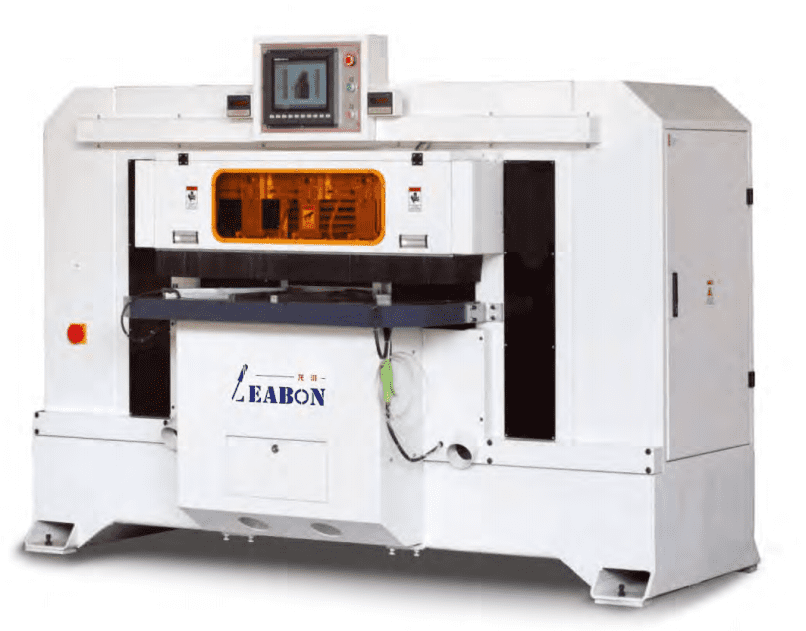

The CNC mortise and tenon machine is a CNC woodworking machine specifically developed for imitation classical furniture and new Chinese style furniture. It integrates multiple functions such as milling holes, milling grooves, milling shapes, and setting lines, making operation more convenient and user-friendly. Compared with traditional equipment, this machine can not only produce standard mortise and tenon structures on the market, but also supports customized production to meet the personalized needs of different customers. The modular production mode further simplifies the operation process; users only need to input material specifications and other data, and the machine can automatically complete the processing, improving production efficiency and quality stability.

04. In-depth Optimization for Specific Products

Among the many categories of solid wood furniture, the production of doors and windows has its own unique characteristics. The door and window processing center is specifically designed for doors and windows, and is an integrated milling and tenoning machine. It can efficiently complete the milling and tenoning tasks for doors and windows, supporting tenon and mortise processing at various angles such as 45°, 90°, and 135° to meet the needs of different door and window designs. Through in-depth optimization, this equipment not only improves the efficiency of door and window processing but also ensures processing quality, making the production of door and window products more efficient and precise.

05 Conclusion

If you have any questions about the Mortise and tenon craft chain, please contact us.

Vivian – Leabon5@ileabon.com

– Whatsapp/wechat:+86 18929978005