Your workshop is only as efficient as the tools within it. Whether you are running a high-volume furniture factory or a boutique carpentry shop, woodworking machinery represents a massive capital investment. The difference between a machine that lasts 20 years and one that fails in five often comes down to one thing: preventative maintenance.

Neglecting regular upkeep doesn’t just shorten the lifespan of your industrial equipment; it leads to poor cut quality, safety hazards, and expensive machine downtime. To help you maximize your ROI, we have compiled an essential maintenance checklist that covers every aspect of machine care.

1. Master Your Dust Collection Strategy

The number one enemy of woodworking machinery is sawdust. Fine dust particles can infiltrate motors, clog gears, and cause overheating.

-

Internal Cleaning: Don’t just sweep the floor. Open the cabinet doors of your table saws and planers weekly to vacuum out trapped dust.

-

Check the Airflow: Ensure your dust collection system is operating at peak efficiency. Clogged filters or leaky hoses reduce suction, allowing dust to settle on sensitive electronic components and lead screws.

-

Rust Prevention: Sawdust absorbs moisture from the air, which traps humidity against cast iron tables. Keeping surfaces clean is the first step in rust prevention.

2. Proper Lubrication: The Lifeblood of Machinery

Friction causes heat and wear. However, simply spraying WD-40 on everything is a rookie mistake. Different parts of your woodshop equipment require specific types of lubrication.

-

Dry vs. Wet Lube: For exposed gears and trunnions, use a dry lubricant (like PTFE or Teflon-based sprays). Wet grease attracts sawdust, creating a gummy paste that can jam height adjustment mechanisms.

-

Bearings: Listen to your machine. A high-pitched squeal usually indicates that the motor bearings or arbor bearings are drying out and need immediate attention or replacement.

3. Regular Calibration for Precision Accuracy

If your cuts aren’t square, it might not be user error—it could be machine drift. Vibration from daily use causes woodworking tools to lose their alignment over time.

-

Table Alignment: Regularly check that your miter slots are perfectly parallel to the blade.

-

Fence Squareness: A fence that isn’t 90 degrees to the table will result in wasted material. Use a high-quality machinist square to verify your rip fence alignment monthly.

-

Planer Tables: For thickness planers, ensure the bed rollers are adjusted correctly to prevent snipe (gouges at the end of the board).

4. Inspect and Sharpen Tooling

Your machine is the muscle, but the blade is the talent. Running woodworking machinery with dull tooling forces the motor to work harder, increasing the risk of burnout.

-

Blade Condition: Inspect circular saw blades and router bits for chipped teeth or resin buildup.

-

Pitch Removal: Resin and pitch from pine or sap-heavy woods increase friction. Clean your blades with a specialized pitch remover to restore their cutting edge before deciding to sharpen them.

5. Electrical and Safety Mechanism Checks

Safety is paramount in any industrial setting. A well-maintained machine is a safe machine.

-

Emergency Stops: Test your E-stop buttons regularly to ensure they cut power immediately.

-

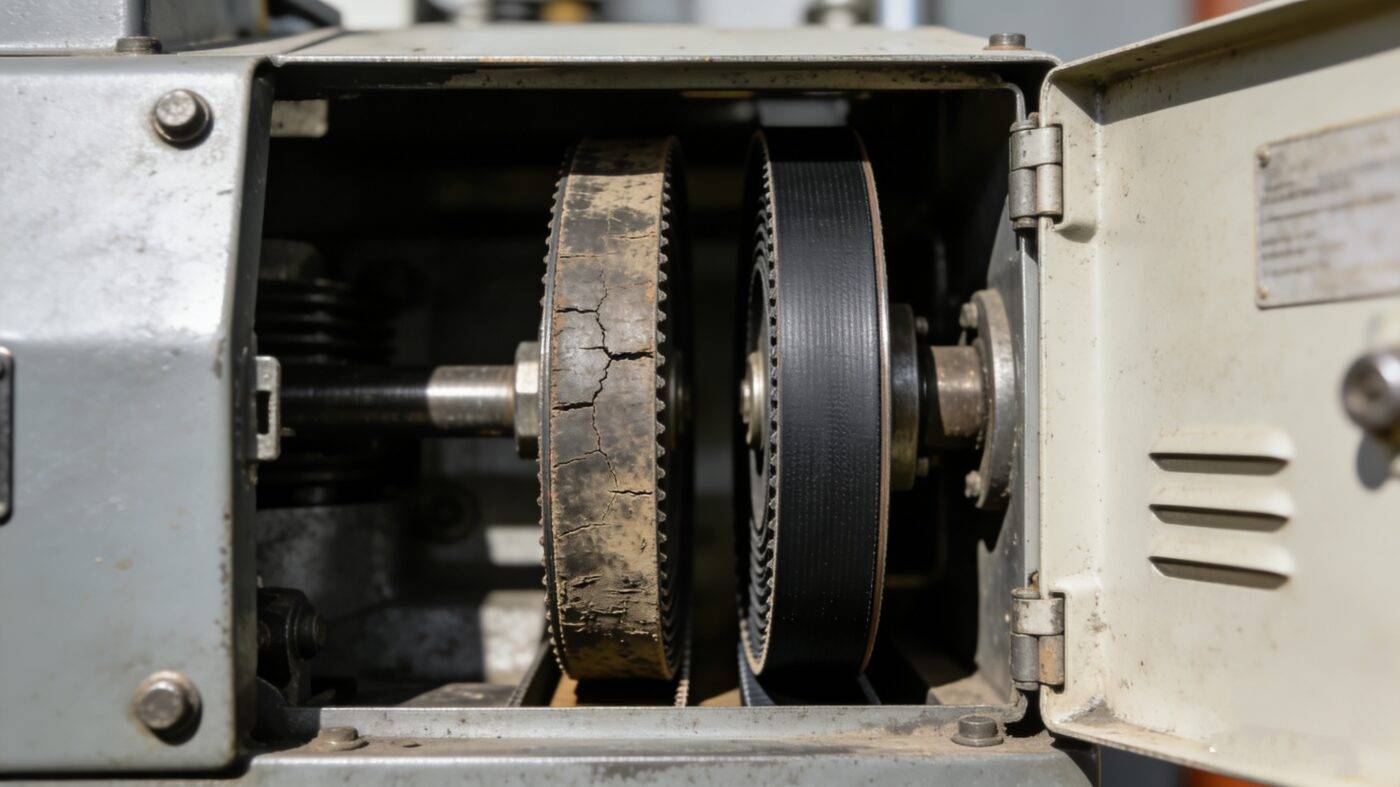

Drive Belts: Check V-belts for cracks or fraying. A slipping belt reduces power transmission and causes vibration in the cut.

-

Power Cords: Inspect electrical cords for damage to prevent short circuits, especially in mobile equipment.

Conclusion

Implementing a strict maintenance schedule for your woodworking machinery is not just about cleaning; it’s about protecting your business’s bottom line. By managing dust, keeping parts lubricated, and ensuring precise calibration, you ensure that your workshop remains productive and safe.

Don’t wait for a breakdown to pay attention to your tools. A small investment of time today will save you thousands in repairs tomorrow.