In the furniture manufacturing industry, sawing has always been a crucial step in solid wood processing. A flat and precisely cut board is often the foundation for producing high-quality furniture. However, as market demands for furniture quality and production efficiency increase, the limitations of traditional band saw equipment have become increasingly apparent. Against this backdrop, a new type of equipment – the vacuum-assisted horizontal band saw – has emerged. With its series of innovative technologies, it brings a new breakthrough to solid wood processing.

01. Shortcomings of traditional band saw equipment

02 Vacuum Suction Horizontal Bandsaw Machine

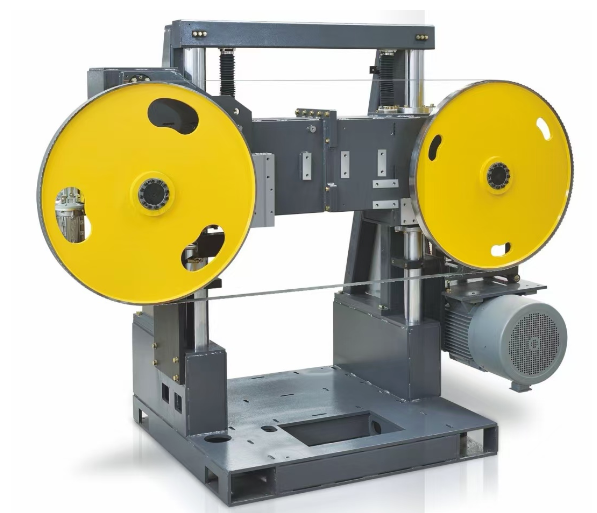

The vacuum suction horizontal bandsaw machine is a new type of wood processing equipment that solves many problems of traditional bandsaw machines through a series of innovative technologies. One of the core features of this equipment is its reinforced overall structure. The machine base adopts a gantry-type frame, with a thick steel plate box-type crossbeam and Ø100 precision steel columns for guidance and support. The overall load-bearing capacity is several times greater than that of traditional horizontal saws.

Another core component of the equipment is its vacuum suction system, which securely fixes the wood to the workbench, ensuring stability during the sawing process. This suction method not only prevents displacement and vibration of the wood during processing but also significantly improves processing accuracy.

In addition to the vacuum suction system, the vacuum suction horizontal band saw is also equipped with advanced saw wheel manufacturing core technology. Its saw wheels are made of high-strength materials, possessing higher rigidity and stability, and are able to withstand the impact forces generated by high-speed sawing. This design not only extends the service life of the saw wheels but also improves the accuracy and quality of the sawing.

The saw blade monitoring system is another highlight of this equipment. By real-time monitoring of the saw blade’s operating status, the equipment can promptly detect and address abnormal situations, such as loosening or misalignment. This not only ensures the stability and safety of the sawing process but also extends the service life of the saw blade and reduces equipment maintenance costs.

Furthermore, the vacuum suction horizontal band saw machine is equipped with an intelligent operating system. Its user interface is simple and intuitive, making it easy to use and significantly reducing the technical skill requirements for operators. With simple training, ordinary workers can operate the equipment proficiently, thereby improving the company’s production efficiency and management level.

03 Breakthroughs in Sawing Quality and Efficiency

The emergence of vacuum-clamping horizontal band saw machines has brought about significant improvements in quality and efficiency in solid wood processing. Firstly, in terms of precision machining, the vacuum clamping system securely fixes the wood to the worktable, ensuring stability during the sawing process. This stability significantly improves sawing accuracy, allowing for the production of flatter and more precise boards. This is crucial for subsequent furniture manufacturing, as it reduces assembly problems caused by uneven boards, thereby improving the overall quality and lifespan of the furniture. The new generation of vacuum-clamping horizontal band saws produces virtually no deformation after sawing, and its precision is even more outstanding in composite and thermoforming processes, meeting the demands of high-precision machining.

For high-efficiency sawing, the vacuum-clamping horizontal band saw is equipped with high-performance saw wheels and blades. These components can withstand higher sawing speeds and perform exceptionally well on difficult-to-process materials such as hardwoods. Compared to traditional band saws, this equipment offers several times faster sawing speeds, significantly shortening production cycles and improving production efficiency. This is a huge advantage for furniture manufacturers, especially when dealing with large orders, and can significantly enhance their competitiveness.

04 Summary

The vacuum-adsorption horizontal band saw machine, with its high precision, high efficiency, and intelligent features, provides furniture manufacturers with a brand-new solution. It not only addresses the shortcomings of traditional band saw equipment in terms of processing accuracy, efficiency, and material waste, but also significantly improves the quality and efficiency of solid wood processing through a series of innovative technologies, such as the vacuum adsorption system, core saw wheel manufacturing technology, and saw blade monitoring system.