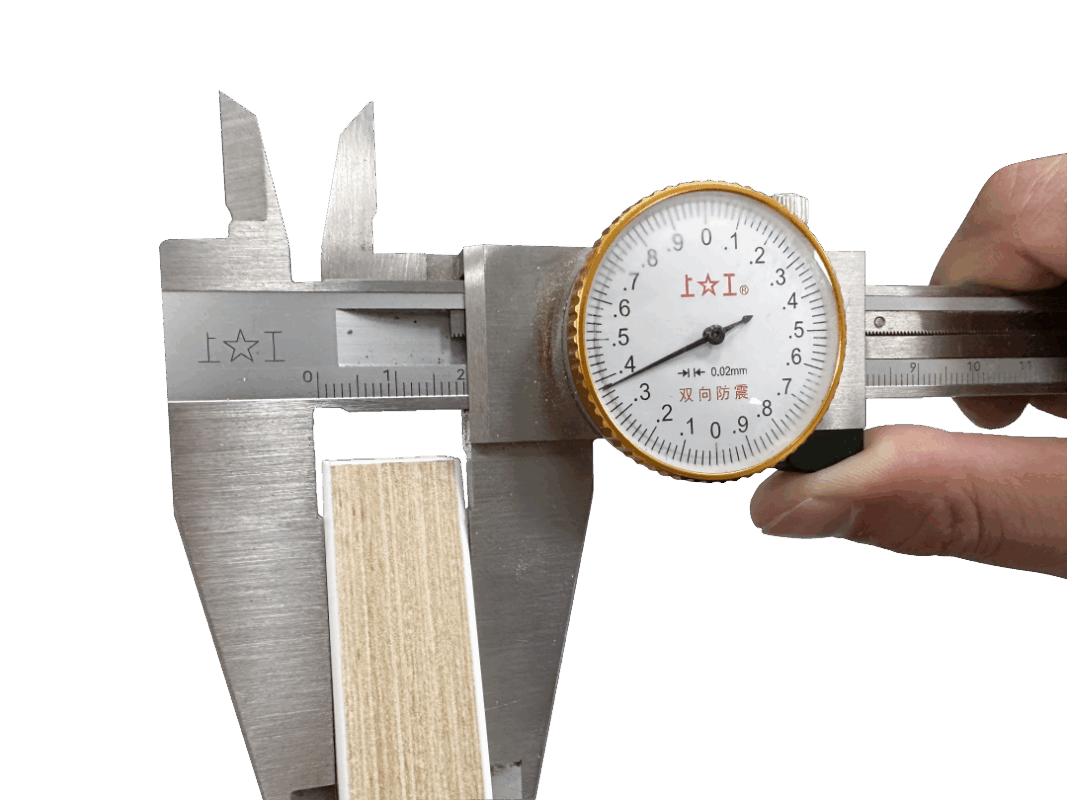

In the field of furniture manufacturing, the need for edge banding of narrow panel components such as drawer side panels, slats, and decorative moldings is becoming increasingly significant. These narrow components not only enhance the functionality of furniture but also add a unique aesthetic appeal. However, traditional edge banding machines are poorly suited for ultra-narrow panels less than 2 cm wide, often resulting in low efficiency and difficulty in controlling quality. This article will introduce a highly efficient edge banding technology specifically designed for widths as narrow as 1.8 cm, providing a brand-new solution for furniture manufacturers.

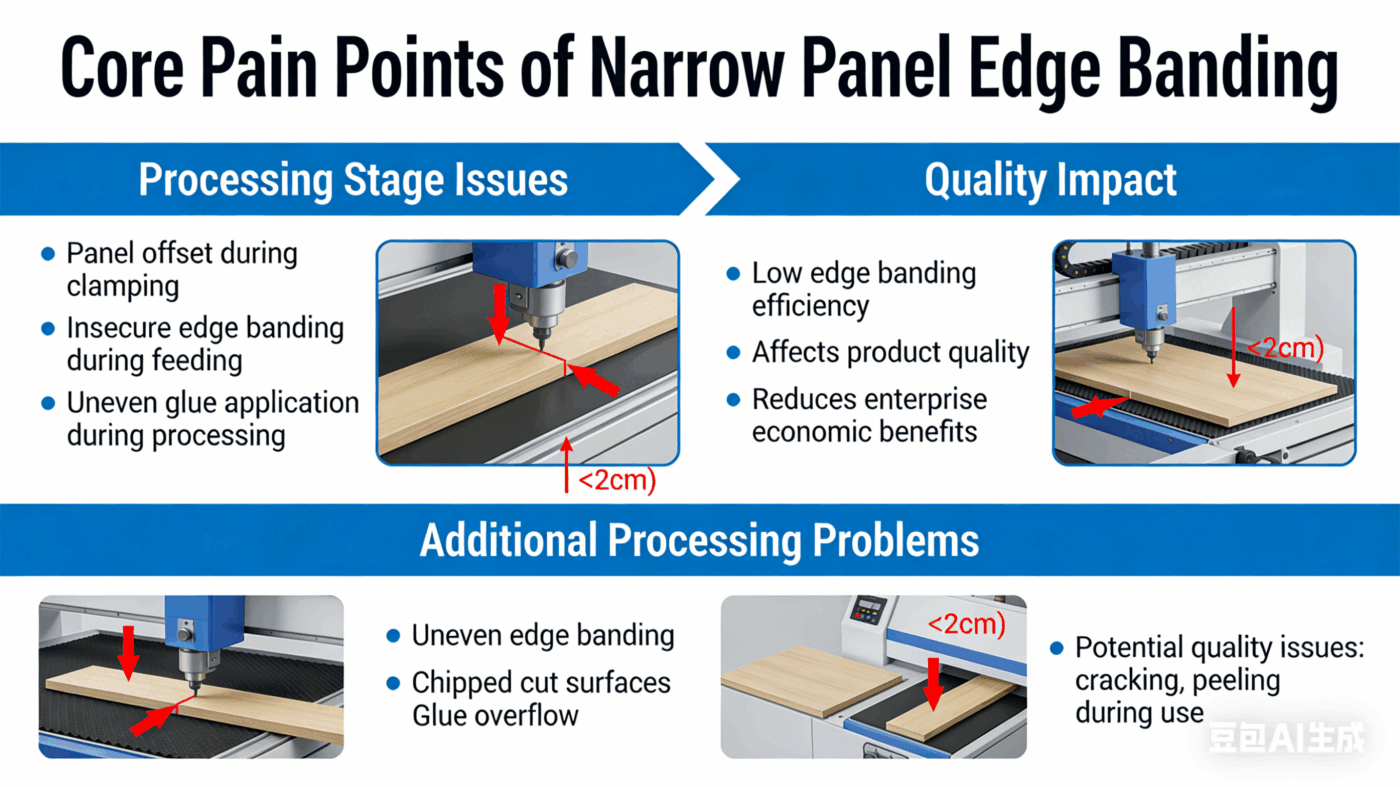

01 Core Challenges and Pain Points in Edge Banding of Narrow Panels

Traditional edge banding machine designs often fail to meet the edge banding requirements of ultra-narrow panels (especially those less than 2cm wide). Due to the small size of narrow panels, traditional equipment is prone to problems such as panel shifting, insecure edge banding, and uneven glue application during clamping, feeding, and processing. These problems not only lead to low edge banding efficiency but also seriously affect product quality and the economic benefits of the enterprise.

Furthermore, due to the size limitations of narrow panels, traditional equipment often encounters problems such as uneven edge banding, chipping of the cut surface, and glue overflow during processing. These problems not only affect the appearance of the product but may also lead to quality issues such as cracking and peeling during product use.

02 High-Efficiency Edge Banding Technology for 1.8cm Wide Panels

(1) Anti-Deviation Feeding Design

The 1.8cm narrow panel edge banding machine features an innovative feeding design, specifically developed for narrow panels. This device utilizes a cylinder-limited panel spacing technology, ensuring that the narrow panels maintain a straight path during feeding, preventing edge banding quality issues caused by panel deviation. This design not only improves the precision of edge banding but also significantly increases production efficiency.

(2) Dedicated Pressure System for Narrow Panels

Due to the narrow width of the panels, traditional pressure systems can easily cause deformation or deviation during the pressing process. The narrow panel edge banding machine uses a design combining a rounded small pressure roller with multiple driven pressure rollers, which precisely distributes pressure and prevents deviation during the pressing process. In addition, the equipment is equipped with an electronic height adjustment and encoder feedback system, which can adapt to panels of different thicknesses from 0.9cm to 6cm in real time, ensuring the stability and accuracy of the pressing process.

(3) Precision Trimming Solution for 1.8cm Narrow Edges

For 1.8cm narrow edges, this edge banding machine employs a precision trimming solution using 45° linear guides and double-blade end-cutting. This design ensures a flat and chip-free edge surface, greatly improving the product’s appearance quality. Furthermore, the equipment is equipped with an independent fine-tuning unit with adjustable motor angle, which can adapt to the precision trimming needs of ultra-narrow edges, further enhancing edge banding quality.

03 How to Ensure the Stability of Narrow Panel Edge Banding

(1) High-Precision Manufacturing of Core Components

The core components of the new narrow panel edge banding machine utilize high-precision manufacturing processes. The key machine body is formed in a single process on an imported high-precision five-axis gantry milling machine, ensuring the machining accuracy and stability of the machine body. In addition, important components are inspected using a coordinate measuring machine, with tolerances controlled within a very small range, guaranteeing the overall performance and service life of the equipment.

(2) Intelligent Error Prevention Mechanism

The new narrow panel edge banding machine is also equipped with various intelligent error prevention mechanisms. For example, when the edge banding tape runs out, the equipment will immediately sound an alarm, reminding the operator to replace it in time, avoiding downtime and quality problems caused by the depletion of the edge banding tape. Furthermore, the equipment has an automatic standby function for idle time; when the machine is not processing panels for more than a set time, it will automatically enter standby mode, reducing tool wear and extending the service life of the equipment.

04 Summary

The 1.8cm narrow-panel edge banding machine, with its exceptional technological innovation and efficient and stable performance, provides an ideal edge banding solution for panel furniture manufacturers. Through high-precision manufacturing of core components and intelligent error prevention mechanisms, this equipment not only effectively addresses the shortcomings of traditional edge banding machines in narrow-panel applications but also significantly improves production efficiency and product quality.