Core Function and Design

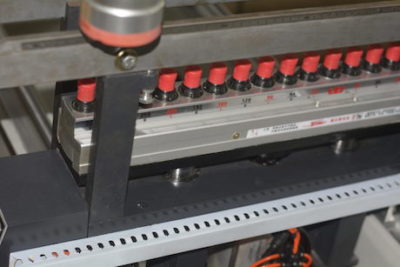

Unlike a standard single-spindle drill, a multi boring machine features a series of drilling heads mounted on a single horizontal shaft. These heads, often adjustable along the shaft, can be spaced to match specific drilling patterns. A typical machine drills a horizontal row of holes into the edge or face of a workpiece, such as a cabinet side panel. This pattern is essential for inserting shelf pins, connector bolts, or dowels—the fundamental hardware for assembling modular cabinets, bookcases, and wardrobes. The machines range from simple, manually fed models to fully automated CNC units with vertical drilling capabilities and digital positioning systems.

Key Advantages for Production

The primary benefit is unmatched efficiency. A multi bore machine can create an entire row of holes in a single, rapid pass, replacing dozens of individual drilling operations. This drastically reduces production time and labor costs. Furthermore, it guarantees absolute consistency and perfect alignment. Every hole in the batch is drilled at the same depth, with precise spacing, eliminating human error and ensuring components fit together flawlessly during assembly. This repeatability is critical for mass production and maintaining high-quality standards.

Applications and Evolution

While most ubiquitous in kitchen and office furniture factories, multi boring machines are also indispensable for door and window manufacturers, and custom cabinet shops seeking to optimize their workflow. Modern iterations often integrate with computer-aided design (CAD) software. CNC-controlled machines can automatically adjust drill head positions and execute complex hole patterns across multiple faces of a panel, pushing the boundaries of design flexibility and setup speed.

In conclusion, the multi boring machine is far more than just a drill. It is a dedicated efficiency engine that delivers the structural precision upon which modern fitted furniture relies. By automating a repetitive but critical task, it allows workshops to enhance throughput, improve product quality, and remain competitive in a demanding industry.