Imagine you have a piece of rough, raw wood. You want to turn it into a smooth table, a sturdy chair, or a beautiful cabinet. Doing all that by hand with saws and chisels is slow and requires great skill. This is where woodworking machines come in. Think of them as powerful, precise helpers that make working with wood faster, safer, and more accessible for everyone, from professionals to hobbyists.

At the heart of any workshop are a few key machines. Let’s meet them.

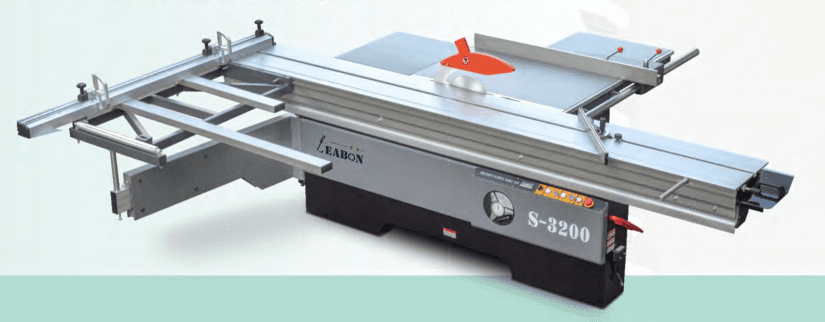

First is the Table Saw. This is often the central machine. A sharp, circular blade sticks up through a slot in a metal table. You push the wood across the table into the spinning blade to make straight cuts, known as ripping (cutting with the wood grain) or cross-cutting (cutting across it). It’s perfect for breaking down large sheets of plywood or cutting boards to width.

Leabon Sliding Table Saw S3200

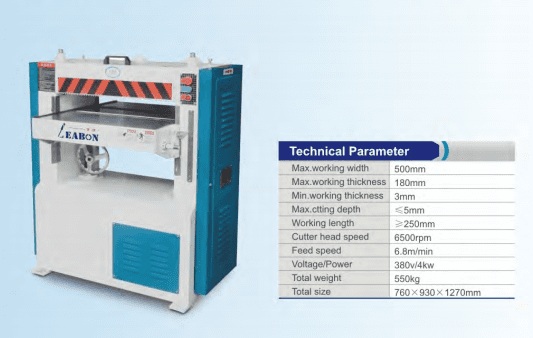

Next is the Thickness Planer. Wood from the lumberyard is often uneven. The planer’s job is to make one side perfectly flat and parallel to the other, giving you wood of a consistent thickness. You feed the board in, and rotating blades inside shave off a thin layer. It’s like a giant, ultra-precise pencil sharpener for boards!

Thicknesser and Surface Planer

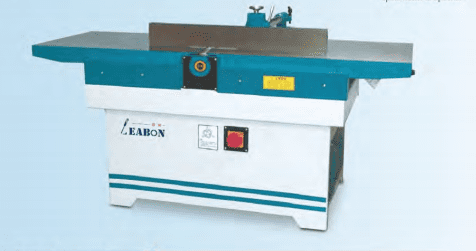

Then we have the Jointer. This machine works hand-in-hand with the planer. While the planer ensures consistent thickness, the jointer creates a perfectly flat face and a perfectly square edge on a board. This is the essential first step before you can build anything with tight, seamless joints.

For cutting curves, circles, or complex shapes, the Band Saw is the hero. It uses a long, thin, flexible blade that runs in a continuous loop between two wheels. Because the blade is narrow, it can twist and turn, allowing you to cut delicate shapes that are impossible with a table saw.

Two Different Bandsaw from Leabon.

Finally, the Router is the master of detail. This handheld or table-mounted tool spins a cutting bit at very high speed. It can hollow out areas (like for a door hinge), create decorative edges (like rounded or patterned profiles), and cut precise joints. It’s incredibly versatile.

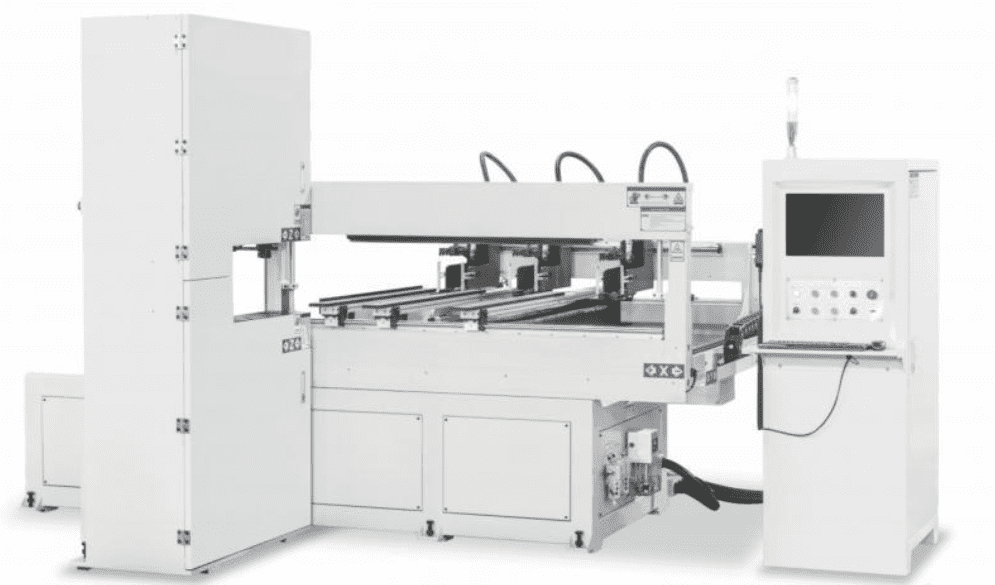

Modern woodworking machines are becoming smarter and safer. Many now come with safety features like blade guards, riving knives, and automatic braking systems. Dust collection ports are standard, keeping the workshop cleaner and healthier. New computer-controlled (CNC) machines can even carve intricate designs automatically from a digital file!

In short, woodworking machines are not here to replace the craftsman’s creativity and touch. Instead, they handle the heavy, repetitive, and risky tasks. They turn the hard work of preparing the wood into a simple, reliable process. This frees you up to focus on the most rewarding part: the design, the assembly, and the final finish—bringing your creative vision to life from a simple piece of wood. With these mechanical partners, the journey from a rough plank to a finished masterpiece becomes smoother, faster, and much more enjoyable.