Perfect edge sealing plays a connecting role in the production of panel furniture.

The edge sealing process is complicated, and if there is no rich operating experience, quality problems are easily appeared. With the arrival of winter, the temperature will also drop, and the edge banding process that has certain temperature requirements will show some different bad points.

We know that in furniture manufacturing, the edge band and the board are bonded through hot melt adhesive (adhesive). The so-called bonding is the capillary pores of the substrate (edge band, veneer and board) and hot melt adhesive. A physical phenomenon of infiltration and mechanical occlusion. This kind of bonding is greatly affected by environmental conditions. In winter, the ambient temperature is low, and the panel’s temperature to be bonded is also low, so the temperature-affected characteristics are greater.

So in the cold winter, what are the common edge sealing problems in the production of panel furniture?

Edge banding

1.The edge banding strips fall off or the tensile strength is not good.

The hot melt adhesive is mainly composed of thermoplastic resin and thermoplastic elastomer EVA, which is greatly affected by temperature. When the ambient temperature in winter is low, the hot melt adhesive coated on the substrate will soon be taken away by the surrounding low-temperature air and the substrate, which shortens the exposure time of the hot melt adhesive, and forms a surface film on the surface , Blocking out the hot melt adhesive infiltration, resulting in false adhesion or poor adhesion. To solve this problem, you can use the following methods:

1.1 Before edge banding, preheat the panel material. The ambient temperature affects the bonding strength. The board must be preheated before the edge banding, especially in winter. Before the edge banding operation, the plate should be placed in the workshop in advance to keep the plate temperature the same as the workshop temperature, or the plate should be heated by small solar lamps one night in advance. Of course, it is best to install heating in the production workshop, but the cost of this solution is relatively high.

1.2 Appropriately increase the set temperature of the hot melt glue tank and the glue roller On the basis of the original set temperature, the temperature of the hot melt glue tank will increase by 5-8℃, and the temperature of the glue roller will increase by 8-10℃.

1.3 Properly adjust the pressure of the edge banding machine if the pressure is low during edge banding in winter, it is easy to cause air gaps between the hot melt adhesive and the panels, which prevents the hot melt adhesive from producing the best infiltration and mechanical engagement with the panels, resulting in false Sexual bonding and poor bonding. To solve this problem, check the sensitivity of the pressure wheel, the accuracy of the display instrument, the stability of the air supply system, and adjust the pressure appropriately (thin side 1-1.5Pa, thickness 1.5-3Pa).

1.4 Other methods

① Properly increase the edge banding speed to avoid the hot melt adhesive exposed to the cold air for too long;

② Check whether the back coating of the edge band is qualified. After the edge banding is completed, pull off PVC tape to check whether there is any glue or sawdust at the bottom of the edge banding. If there is no glue or sawdust, it can prove that the edge banding back coating is unqualified or the edge banding hot melt adhesive is unqualified;

③Check whether the plate is too loose or the plate is unqualified, and whether the plate stacking time is too long and the port has too much dust.

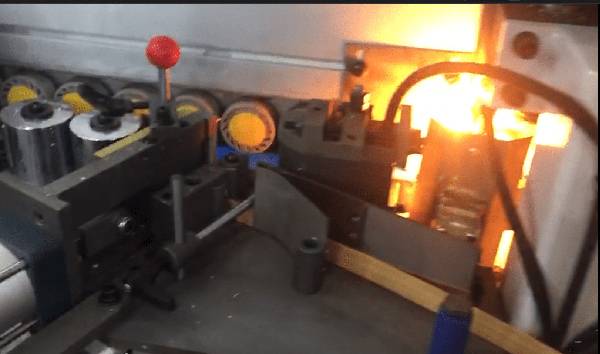

Heating Gun for Gluing

2.Slotting is easy to chip and degumming.

Thermoplastics are greatly affected by temperature. The lower the temperature, the easier it is to cold shrink. Hot melt adhesives and edge banding are no exception. They will further harden as the temperature decreases and cause internal stress at the bonding interface. When the impact force of the grooving tool acts on the bonding interface, the internal stress is released, causing chipping or degumming. To solve this problem, the temperature of the plate during grooving can be adjusted to above 18°C, so that the soft elastic hot melt adhesive can alleviate the impact force of the tool; or change the direction of rotation of the tool so that the impact force of the tool acts on the surface of the edge banding strip; Or reduce the slotting advancing speed and grinding the slotting tool frequently to reduce the impact force of the tool.

3.The wiredrawing of edge banding.

Generally speaking, the situation of wiredrawing is mainly when using transparent glue to seal the edge. Especially in winter, the temperature difference between indoor and outdoor temperature is large, and air convection will cause the temperature environment. Changes occurred, leading to the wiredrawing situation. In addition, if the temperature is too high or too low, and the amount of glue applied is too large, there may be wiredrawing. It is recommended that the furniture factory adjust properly machine according to the temperature.

The environment, the performance of the equipment, the quality of the materials used, the operation technology and the regulations will all have an impact on the bonding quality of the edge banding. Therefore, to obtain a good edge banding effect and manufacture high-quality furniture, various factors must be fully considered. The influence of the edge banding process. From process equipment, material technology, to processing procedures, etc., in the selection of edge banding and hot melt adhesive, it is necessary to choose a product with high quality and good reputation. After talking about the common edge banding problems in winter and the corresponding solutions, the editor would like to change the angle and analyze the many factors that affect the edge banding effect, so that when you find the problems, you can find the causes by sorting them out one by one.

4.Analysis of factors affecting the effect of edge sealing

4.1 The temperature of glue pot

If the temperature of the glue pot is too high, the hot melt adhesive will oxidize and burn, thereby changing the adhesive properties and adversely affecting the adhesive force. In addition, if the temperature of the hot melt device is too low, the hot melt adhesive cannot be completely liquefied, resulting in uneven glue application and weakened adhesion.

4.2 Plate temperature

Only when the plate temperature is above 15℃ can it have a good bonding effect. If the temperature of the sheet is too low, the temperature of the hot melt adhesive will drop rapidly when it comes into contact with it, resulting in a decrease in the liquefied state of the hot melt adhesive and affecting its adhesion and penetration.

4.3 The production speed

It should be adjusted according to different panels, edge banding and hot melt adhesive. When the speed is increased, the hot melt adhesive will be kept in a liquefied state, which can strengthen the penetration of the sol, but the relative cooling time will also be reduced. On the contrary, setting the production speed at a slow speed will allow the hot melt adhesive to have a longer time to cool down, but it will affect the adhesion and penetration and lead to poor adhesion.

4.4Roller pressure

Without proper and sufficient pressure, it will affect the bonding effect. Adjusting the pressure should be based on the liquid condition of the adhesive material and hot melt adhesive. Generally speaking, the lower the liquid condition, the greater the pressure required. Conversely, the higher the liquid condition, the lower the pressure required, because it can maintain the hot melt. The penetration of the glue makes the bonding more successful. When bonding solid wood with improper pressure, many problems will occur, especially when bonding some curved or thick objects. Therefore, it is necessary to master certain skills and set a suitable pressure in order to have a good bonding effect.

In general, the working process of hot melt adhesive is mechanical heating→melting→coating→pressurizing→bonding. In order to achieve the best bonding effect, the relevant indicators of the first 4 factors must be consistent with the relevant parameters of the hot melt adhesive. The principle of using hot melt adhesive in winter and boiling water in winter is the same. The lower environment and temperature absorb part of the heat of the hot melt adhesive, and shorten the open time of the hot melt adhesive, that is, the “exposure time”.

5.Summary of the method of edge banding in winter

To sum up, if the edge banding falls off or the bonding effect is not ideal in winter, please follow the steps below.

①Measure the temperature of the rubber coating wheel.

②Check if there is any precipitation at the bottom of the glue tank (normal heating).

③Check whether the heating tube is working normally (normal heating).

④The temperature is increased by 10℃-20℃.

⑤Increase gluing volume.

⑥Increase the pressure.

⑦Improve the working speed of the edge banding machine.

⑧ Check whether the edge-sealing coating is qualified, and test the edge-sealing strips with different product colors or batches.

⑨ Mix or replace products with low softening point and viscosity.