How to choose the right tool based on materials and equipment

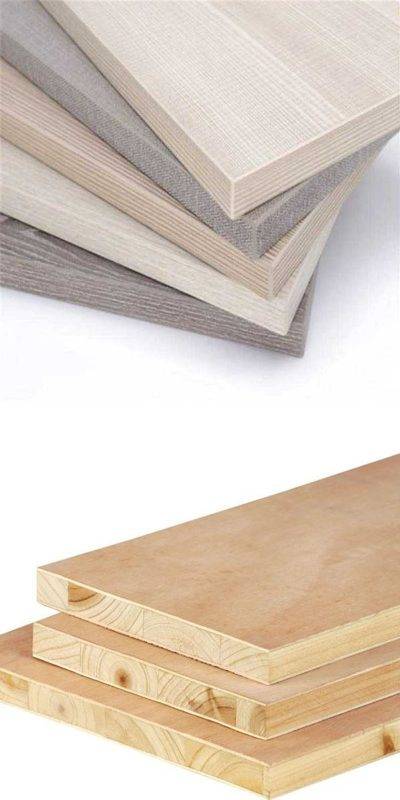

1. Solid wood: refers to a variety of native wood boards without excessive artificial processing; (including large core boards, plywood (multi-layer boards))

2. Artificial boards: boards or pressed products made from wood or other non-wood plants as raw materials, separated into various unit materials through certain mechanical processing, and then glued together with or without the application of glue and other additives. This includes particle board, density board, melamine board, etc.

How should we choose cutting tools based on the above-mentioned boards?

First of all, solid wood

This type of board does not have excessive impurities.

There are two options for original ecological solid wood:

1. Use a traditional welded ordinary straight knife (for logs only);

2. Use TCT straight knife (for logs only)

Be sure to choose logs, because this kind of virgin board that has not been artificially processed will have “nodules”. The “nodule” part is relatively hard, so an alloy material with a relatively low hardness should be selected. This is the theory of “softness overcoming hardness”.

There are two options for plywood (multilayer board):

1. If the smoothness requirements are not high, you can use TCT straight knife;

2. For high smoothness requirements, a single-edged spiral fluting knife can be used; the reason is that the plywood (multi-layer board) industry is called a thin core board, which is made of three or more layers of one millimeter thick veneers or thin plates that are glued and hot pressed. . Its characteristic is that the wood in the plywood is unstable and sometimes consists of several or more types of wood with different hardness and fiber sizes. The wood fiber is relatively strong and there are too many glue impurities and other problems. For general tools, the surface finish of the workpiece processed is poor and prone to burrs.

Straight edge relief angle allows for better cutting, and the blade body is more durable.

Innovative “V” shaped step edge

Additional drilling function to easily complete hundreds of drilling operations

High-quality hardware, imported materials from Europe, sharp and strong cutting edge, smooth and smooth cutting of impurities in the board;

Pioneer’s design cleverly uses physical principles to reduce the damage caused by impurities in the plate to the knife body, allowing one knife to complete multiple batches

Artificial panels:

Particleboard:

It is characterized by excessive impurities, glue and other ingredients inside the board. Generally speaking, cutting tools are prone to wear, chipping and other phenomena. To process this type of plate, customers are recommended to use TCT straight knives. Density board:

Also called fiberboard, it is characterized by high hardness and a large amount of adhesive ingredients. Generally speaking, the cutting edge of knives is prone to wear and tear, and even more so, the knife may break.

To process this type of plate, it is recommended that customers use European alloy TCT straight knife (special for cutting) melamine plate:

It is also called a double-veneer panel by some and is called an ecological board in the industry. It is characterized by excessive hardness and excessive impurities and adhesives inside the board. In particular, a layer of melamine on the surface corrodes the alloy very much. General tools are prone to wear, breakage, and edge chipping on the surface of the plate. To process this type of plate, you can choose European alloy TCT straight knife (special for veneer panels)

The processing equipment currently used by furniture factories can be roughly divided into two categories:

1. Ordinary categories: hanging gongs, floor gongs, portable gong machines, etc. It is recommended to use ordinary straight knives.

This type of processing equipment generally suffers from the following problems:

1 Most of them are manual operations, and the human factor is relatively large.

2 Most of the workpieces processed are in the form of prototypes.

3. Unstable factors during processing: uneven feed, sometimes fast and sometimes slow.

4. The surrounding environment of the machine is not demanding.

The occurrence of the above factors will directly affect the service life of the tool.

2. CNC type: rod groove machines, computer engraving machines, CNC machining centers, etc. It is recommended to use TCT straight cutters or solid alloy cutters.

Most of this type of processing equipment is numerically controlled, with a relatively high degree of automation, good accuracy and stability, and there are no personal factors.