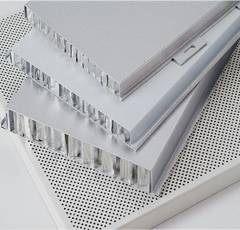

Why Edge Banding is Non-Negotiable for Aluminum Honeycomb Panels

Beyond Aesthetics: Core Functions

These specialized machines are vital for panel longevity and performance. They precisely apply a protective edge sealing strip (typically aluminum, sometimes PVC/composite) to the panel perimeter. This process:

-

Seals the Core: Creates a moisture-tight barrier, preventing contamination and protecting the honeycomb structure.

-

Enhances Durability: Shields core and bonds from environmental damage, extending service life.

-

Improves Safety: Eliminates sharp, exposed core edges for safer handling.

-

Elevates Aesthetics: Delivers a clean, professional, finished appearance.

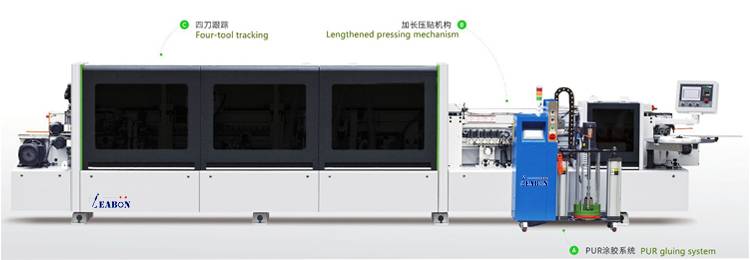

Machinery & Process Overview

Designed for heavy, rigid panels, these machines differ from standard wood banders. Key stages include:

-

Feeding & Positioning: Ensures precise panel edge alignment (conveyors).

2. Edge Prep (Often Crucial): Cleaning and deburring cut edges for optimal adhesion.

3. Adhesive Application: The critical step. High-performance Polyurethane Reactive (PUR) hot-melt is most common, precisely extruded onto the edge or banding. Some applications use cold glues (epoxy/PU).

4. Strip Application: Feeds banding (usually aluminum coil) and presses it firmly onto the prepared edge with alignment guides.

5. Pressure & Curing: Heavy rollers/pads ensure strong bonding. Heat or IR lamps may accelerate PUR cure.

6. Trimming & Shaping: High-precision cutters remove excess banding from panel faces; optional shaping (e.g., rounding) occurs here.

Key Technical Requirements

-

Robustness: Heavy-duty construction to handle aluminum panel weight without deflection.

-

High Precision: Essential for seamless joints and alignment on large panels.

-

Adhesive Handling: Specialized systems for high-temp PUR application (tanks, pumps, nozzles), requiring precise temperature and quantity control.

-

Material Handling: Capability to process large architectural panel sizes.

-

Versatility: Adaptability to various panel thicknesses, core densities, and banding dimensions.

Benefits of Automation

Dedicated edge banding machines offer significant advantages:

-

Consistent, High Quality: Unmatched uniformity and precision vs. manual methods.

-

Increased Throughput: Dramatically faster production.

-

Reduced Labor & Skill Dependency: Minimizes need for highly skilled manual finishing labor.

-

Enhanced Reliability: Guarantees a robust, sealed edge, maximizing panel performance and lifespan.

-

Improved Safety: Reduces operator exposure to sharp edges and hot adhesives.

-

Professional Finish: Meets high aesthetic standards required by architects and clients.

The Aluminum Honeycomb Panel Edge Banding Machine is not merely a finisher; it’s fundamental to product quality and durability. By sealing vulnerable edges and providing a safe, aesthetically superior finish, this specialized equipment ensures aluminum honeycomb panels achieve their full potential in terms of performance, longevity, and visual appeal across all demanding applications. It transforms raw panels into reliable, high-performance solutions.