A Wood CNC (Computer Numerical Control) router is a cornerstone of modern woodworking, seamlessly blending traditional craft with digital precision. This versatile machine automates the cutting, carving, and shaping of wood, transforming raw material into intricate parts with unmatched accuracy.

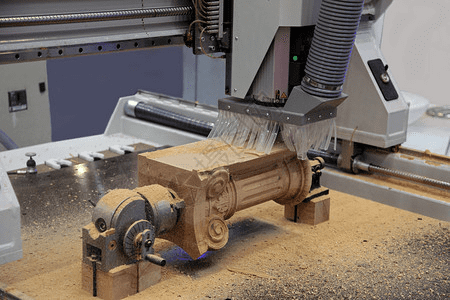

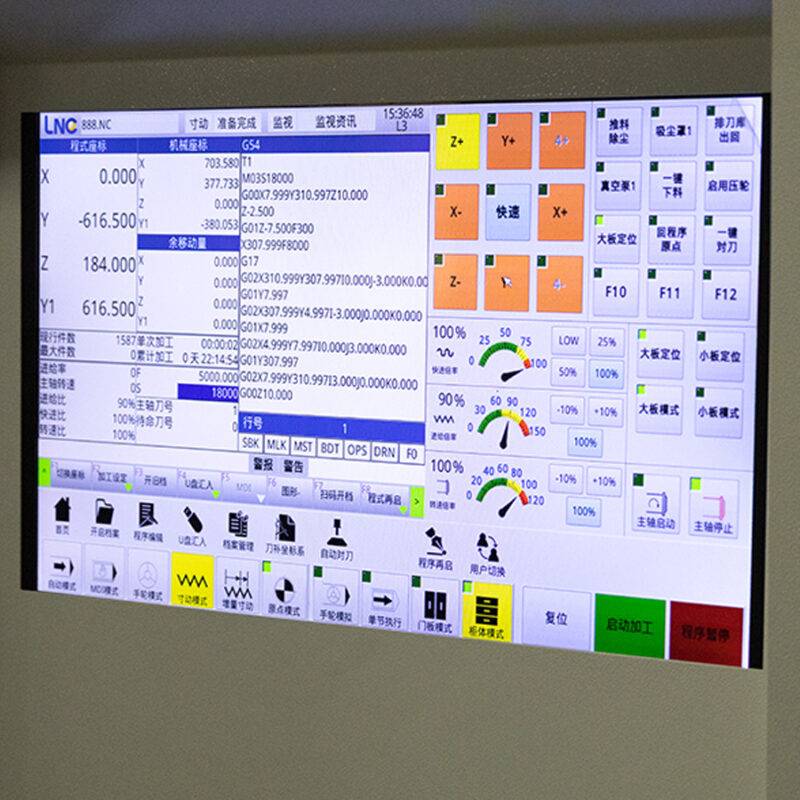

Core Functions: At its heart,a CNC router performs three primary functions: cutting, carving, and engraving. It can effortlessly execute complex 2D profiles for precise part production, create breathtaking 3D relief carvings for artistic pieces, and perform detailed engraving for personalized signs and designs. The machine operates on three primary axes (X, Y, and Z), allowing it to move the cutting tool or spindle in three dimensions to create virtually any shape imaginable from a digital file.

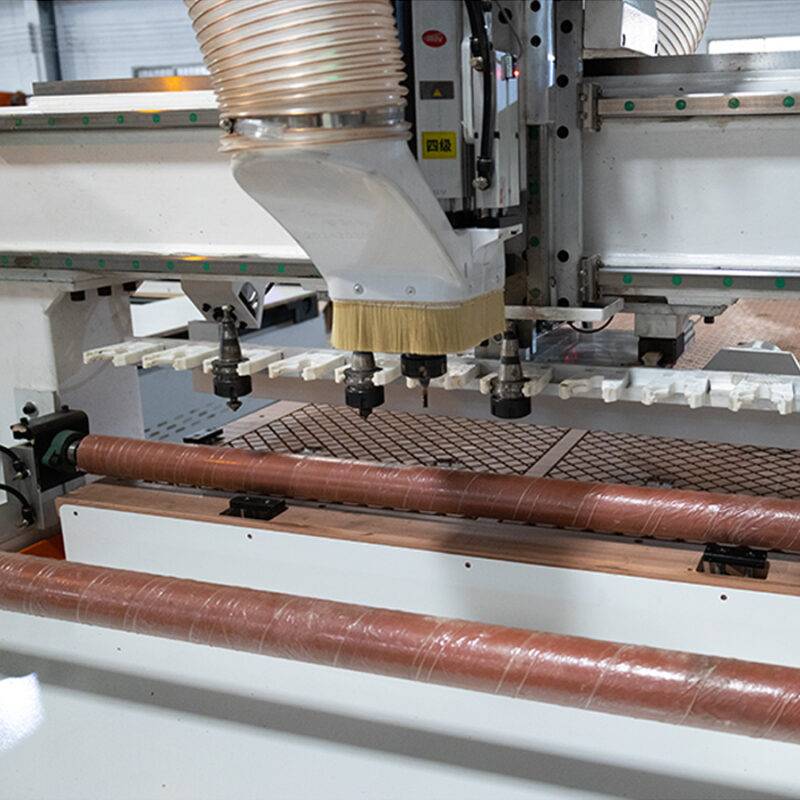

Key Features: Several features define a capable wood CNC router.The spindle, the motor that rotates the cutting bits, is characterized by its power (measured in horsepower) and variable speed control, which is crucial for cleanly cutting different materials. The work bed is the surface that holds the material in place, often using a vacuum system or mechanical clamps. Rigid construction, typically from steel or aluminum, ensures stability and minimizes vibration during operation, which is critical for achieving a smooth surface finish.

Transformative Usefulness: The usefulness of a CNC router is transformative.It brings unparalleled repeatability, allowing for the perfect reproduction of identical parts—essential for furniture manufacturing and production runs. It unlocks creative possibilities, enabling the fabrication of designs that would be nearly impossible to achieve by hand. From crafting custom cabinetry and complex joinery to producing musical instruments and decorative art, the wood CNC router is an indispensable tool that empowers makers to innovate, increase efficiency, and expand their capabilities.