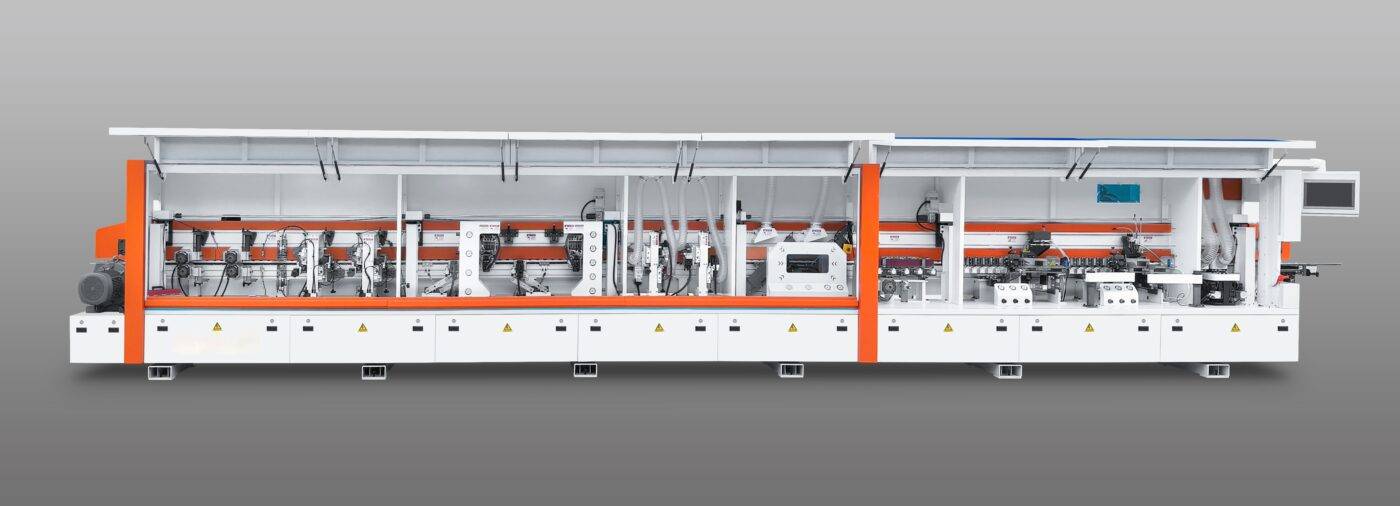

An automatic edge banding machine is a widely used machine in furniture making industry. Its main job is to make the edges of furniture pieces look clean, smooth, and professional. If you have ever seen a desk or a cabinet with a smooth, colored edge, you have seen its work.

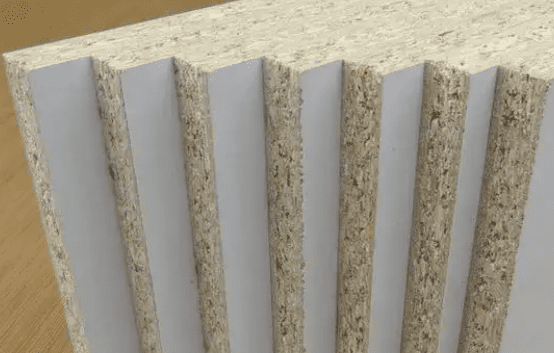

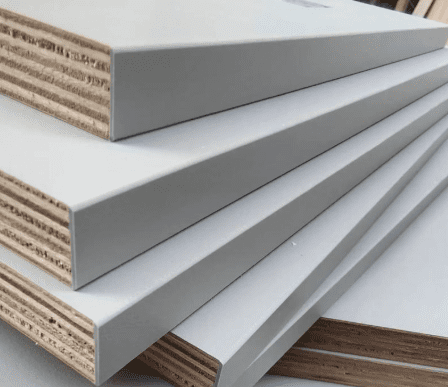

This machine attaches a thin strip, called “edge banding,” to the raw edge of a board. This board is often plywood, particle board or aluminum honeycomb panel. The edge banding itself can be made from many materials. Wood veneer, plastic, or PVC are common choices as well as the solid wood strip. This process covers the rough, unfinished edge underneath.

Why is this so important?

First, it makes the furniture look much better. It gives the appearance of a solid, high-quality piece. Second, it makes the furniture much stronger and more durable. The edge banding seals the board, which protects it from moisture. It also guards against chipping and everyday wear and tear.

Automatic edge banding machine with PUR glue, better effect than using EVA glue.

How the Machine Works Step-by-Step

The whole process is fast and efficient.

1. Premilling: This first step usually is to make the edge side soomth with two milling blade to reach better effect.

2. Gluing: The process starts with glue. A worker places the board into the machine. The machine has a special glue pot that heats up. It melts a solid glue stick. Then, it puts a thin, hot layer of this melted glue onto the board’s edge. The heat makes the glue stick very well.

3. Putting on the Banding: Next, the machine feeds the edge banding strip onto the glued edge. The strip comes from a big roll inside the machine. The banding presses directly onto the hot glue.

4. Pressing it Firmly: Right after, a set of rubber rollers press the banding down with strong, even pressure. This ensures a very tight bond between the banding and the board. There are no gaps or bubbles.

5. End cutting and trimming: Now, the banding sticks out from the board. The machine uses sharp trimming tools to cut away the extra material. One cutter trims the top edge. Another cutter trims the bottom edge. This makes the banding perfectly flush with the board’s surface.

6. Buffing: Finally, the machine smoothens the new edge. A sanding belt lightly sands the sharp corners. Then, a buffing wheel polishes it. This leaves a smooth, rounded feel that is nice to touch.

Automatic edge banding machine for aluminum honeycomb panel

The Big Benefits

Using this machine saves a huge amount of time. Doing all these steps by hand is very slow. The machine does everything in one quick pass.

It also creates a very consistent and high-quality finish. Every piece comes out looking the same, which is great for making many pieces of furniture.

In summary, the edge banding machine is like a magic box for woodworkers. It takes a raw board and gives it a beautiful, strong, and finished edge in just moments. It is a key piece of equipment for creating modern, long-lasting furniture.