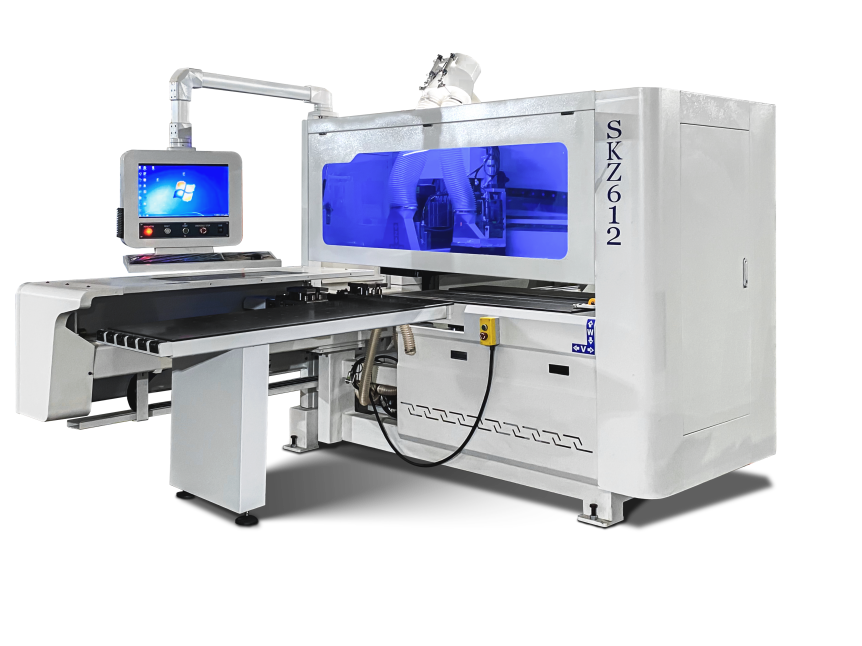

In the modern furniture production field, as consumers’ requirements for furniture quality and design continue to improve, traditional processing equipment can hardly meet enterprises’ dual needs for production efficiency and process precision. The six-sided drilling and milling machining center, with its powerful functions and flexible configurations, is becoming a key choice for many furniture manufacturers to enhance their competitiveness, featuring diversified processes, precise processing, intelligent operation and flexible configuration to provide an efficient, accurate and intelligent processing solution.

Author Archives: Leabon-Vivian

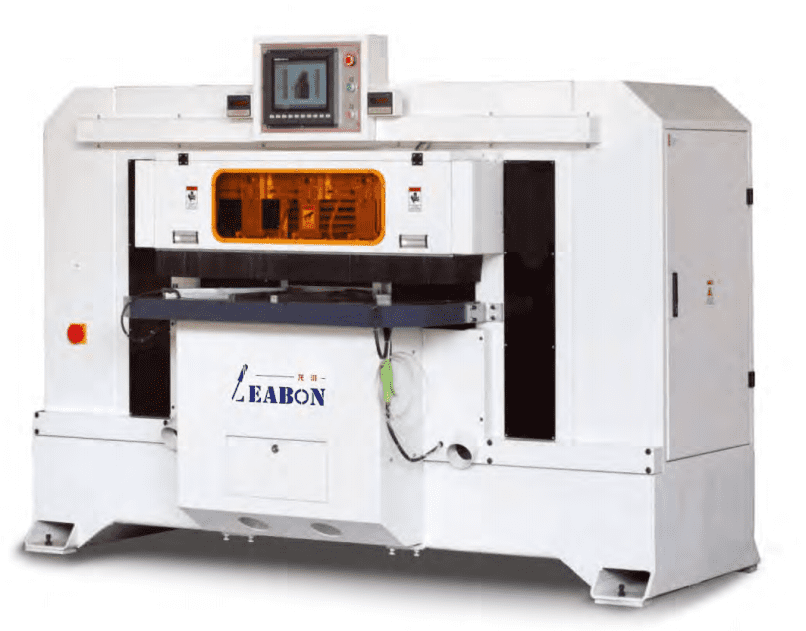

In the furniture production field, as traditional edge banding machines have poor adaptability to ultra-narrow boards (less than 2cm in width) and often cause various quality and efficiency problems, 1.8cm narrow board edge banding machine, with innovative anti-deviation feeding design, special pressing system, precision trimming scheme, high-precision core components and intelligent error-proof mechanisms, provides an ideal solution for furniture manufacturers to improve production efficiency and product quality.

The vacuum-adsorption horizontal band saw machine, with its high precision, high efficiency, and intelligent features, provides furniture manufacturers with a brand new solution.

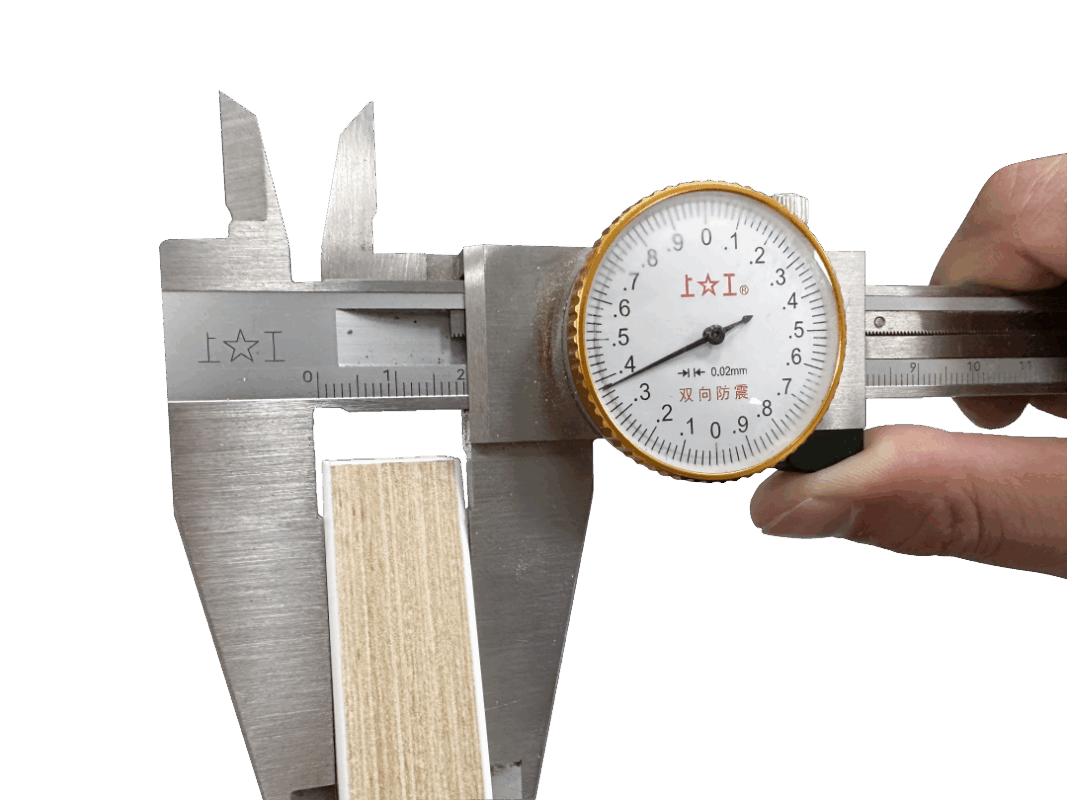

Custom solid wood furniture manufacturers can effectively solve the problems of low efficiency, high cost and unstable quality in traditional production by building a digital process chain of “intelligent material cutting → modular mortise and tenon processing → professional precision processing” and introducing advanced equipment and technology, so as to achieve high precision and fast delivery.

In the furniture manufacturing industry, the veneer process for curved furniture and special-shaped components has always been a headache. Now, we will explore how curved surface presses can improve yield rates from a technical perspective.

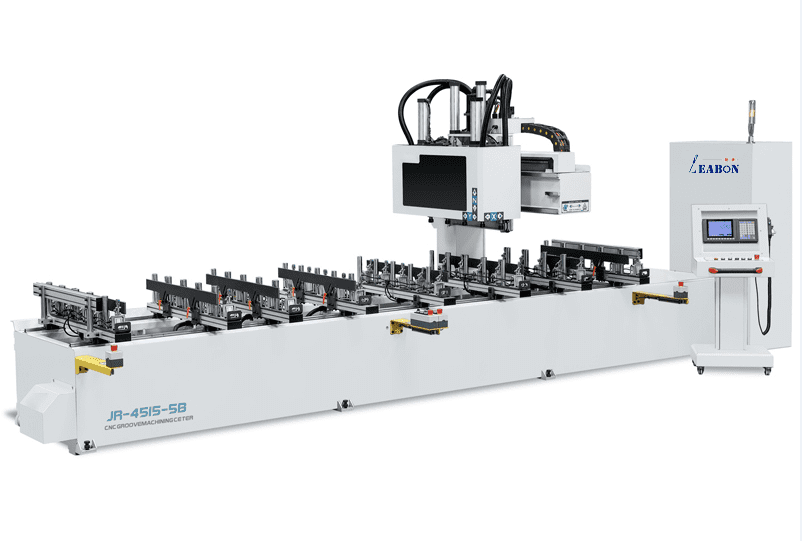

With the continuous advancement of technology, the woodworking industry has embraced the wave of intelligence. As a leading player, the CNC mortising machine has become an important piece of equipment in modern woodworking production lines due to its high efficiency, precision, and flexibility. This article will detail the structure, working principle, application fields, and future development trends of CNC mortising machines.

For wooden door manufacturers, if they want to produce beautiful and exquisite wooden doors more efficiently, a series of wooden door processing equipment is essential.

The electronic saw has poor cutting effect? It’s because you didn’t do these usage details correctly!

With the continuous development of science and technology, the woodworking industry has also ushered in a wave of intelligence.

- 1

- 2